In cement plants, the rotary kiln, serving as the core calcining equipment alongside auxiliary machinery, dominates global cement production due to its efficiency and market prevalence. Alcox's expertise ensures top-notch rotary kiln setups that improves cement plant operations. The rotary kiln is important due to its following advantages:

Alcox specializes in facilitating rotary kiln setups for cement plants that maintain integration and optimal performance. Our expertise in design, construction, and technology implementation guarantees efficient and reliable rotary kiln installations, contributing to the success of cement manufacturing endeavors.

The cement industry experiencing remarkable global growth, necessitates robust infrastructure. Alcox addresses the industry's need for cement storage sheds, safeguarding raw materials, finished products, and ensuring protection during transportation and off-season storage.

Alcox specializes in setting up efficient and durable cement storage sheds and plants including bulk storage and captive thermal power plant, ensuring the longevity and protection of valuable raw materials and finished products in the dynamic cement industry. We are offering turnkey solution of cement plant at an affordable cost with international standards.

We have been working for cement plants in India and overseas from last 28 years . List of our clients and projects shows the reliability of our company. Our state-of-the-art fabrication facilities enable us to be global leaders in the design and production of large span steel structures, space frames and ETFE.

We use to update with the latest technologies of the industry to release wastage in a proper way, minimize wastage and make it reusable. Our equipment and tools are eco-friendly to maintain efficiency of energy. We are committed to following all norms to give an environmentally friendly space. Turnkey cement plant solution is offered environmentally to follow international standards and specifications.

Responding to increasing environmental concerns, cement plants actively adopt sustainable practices that align with environmentally conscious solutions, including the implementation of the turnkey cement plant solution.

The evolution in cement plant technology provides an array of advantages to the construction industry, elevating productivity, efficiency, and quality control standards.

The integrated terminal buildings are designed with number of structural innovations. The key feature of airport structure is their long span roof covering with massive column spacing. The mega columns and large cantilevers make the structure unique. By using modular space frame structure supported by cantilevered columns makes the roof aesthetically good with doubly curved.

Go To Full PageIt offers a futuristic solution for creating durable and efficient structures in cost effective manner. Apart from great flexibility of designing and minimal construction time offered by PEB’s, they are also preferred for their robustness and durability. Moreover, it is possible to add a wide range of structural and non structural components, which enhances their aesthetic appeal and also improve their usability.

Go To Full PageSpace frame is a three dimensional structure. The 3D behavior ensures optimum utilization of material. The quality of roofing is exceptional good as the deflections are almost negligible. Despite their light weight, these structures are designed to carry much heavier load and have a huge spanning capacity. Erection time is minimal as the material is pre fabricated from the factory.

Go To Full PageSteel frames construction is a very popular structural form for multi storey buildings as it provides great flexibility. The structure has adequate strength and stiffness to resist the applied loads due to gravity and wind. The function of the structure in resisting vertical loads due to gravity and horizontal loads due to wind is generally considers separately.

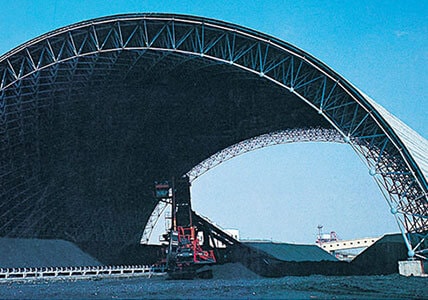

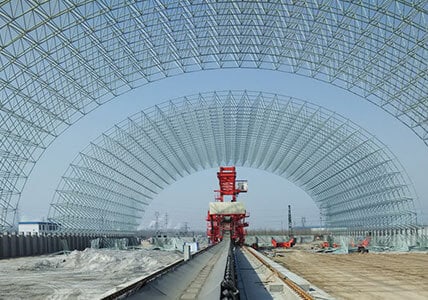

Go To Full PageBulk storage sheds are large span structure to accommodate tons of coals for continuous supply to the boilers.The structures are designed with modular space frame to make it cost effective compared to other conventional structures. Catwalks, ducts and other services can be accommodated within the top and bottom chord.

Limestone Gypsum Additive Iron Ore CoalTextile supported by steel combines the high flexibility of use of this one, from reticular arches to infinite space geometries, with a singular covering applied only with optimum conditions in order to avoid abrasion and corrosion due to contact with main bearing structure. The all season use is guaranteed by a singular system of side opening in order to obtain maximum ventilation in hot season.

Go To Full PageSelf supporting roofing system makes it possible to erect a warehouse in one span without trusses, purlins and rafters. The systems are mechanically sealed which ensures better weather proofing and a hygienic and clean environment. The absence of holes, nuts, bolts, overlaps or sealants, these structures require minimal to zero maintenance making them highly cost efficient.

Go To Full PageTelephone: +91-11-65376653/54

Mobile: +91-9958646644 / +91-9818302640

Fax: +91-11-23588087

Email: info@alcox.in