Pre-Engineered Building (PEB)

In PEB Industry, Buildings manufactured in a way that its structural members are factory manufactured/Engineered are known as Pre Engineered Buildings or PEB. Pre engineered buildings are becoming an emerging trend nowadays in realization of an efficient and cost effective infrastructure. PEB is supplied as a fully finished product by PEB company along with steel structure, metal building accessories and roofing/cladding.

Pre engineered building offers various advantages which makes it an efficient and timely solution to suit unique engineering & design needs of modern building ecosystems.

- Lightweight but robust.

- Reduced construction time from designing to erection phase.

- Effective utilization of space with higher spans.

- Offer high flexibility for expansion & relocation.

- Offer higher salvage value as compared with conventional structures.

Over the past several years, industrial shed manufacturer in India, Hindustan Alcox, has offered pre engineered buildings with diverse specification to meet unique project requirements. Major components of Pre engineered buildings are:

- Primary frames or Main frames

- Secondary frames

- Roof and wall panels

- Structural subsystems (including canopies, fascias, partitions, etc)

- Floor systems (including mezzanines, catwalks, platforms, etc)

- Other building accessories (like sliding doors, roll up doors, windows etc)

With extensive knowledge and expertise in offering tailor-made solution, Hindustan Alcox, a premier in steel building manufacturers in PEB Industry specializes in manufacturing industrial sheds. We are leading Pre Engineered Building Manufacturer in diverse steel building industries including Steel Building manufacturer as well as erection of factory sheds, warehouses, aircraft hangers, shopping malls and office complexes.

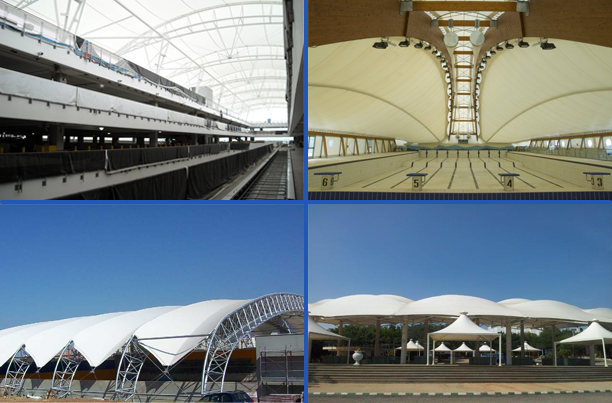

Product Gallery

PRODUCTS & SERVICES

Airports

The integrated terminal buildings are designed with number of structural innovations. The key feature of airport structure is their long span roof covering with massive column spacing. The mega columns and large cantilevers make the structure unique. By using modular space frame structure supported by cantilevered columns makes the roof aesthetically good with doubly curved.

Learn More

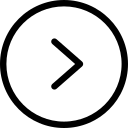

Bulk Storage Sheds

Bulk storage sheds are large span structure to accommodate tons of coals for continuous supply to the boilers.The structures are designed with modular space frame to make it cost effective compared to other conventional structures. Catwalks, ducts and other services can be accommodated within the top and bottom chords.

Coal

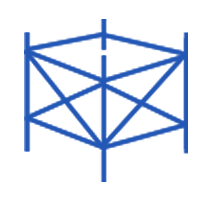

Space Frames

A space frame is a three-dimensional structure. The 3D behavior ensures optimum utilization of material. The quality of roofing is exceptionally good, as the deflections are almost negligible. Despite their light weight, these structures are designed to carry much heavier loads and have a huge spanning capacity. Erection time is minimal as the material is pre-fabricated from the factory.

Learn More

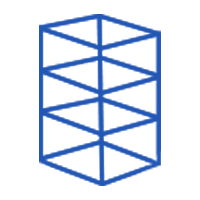

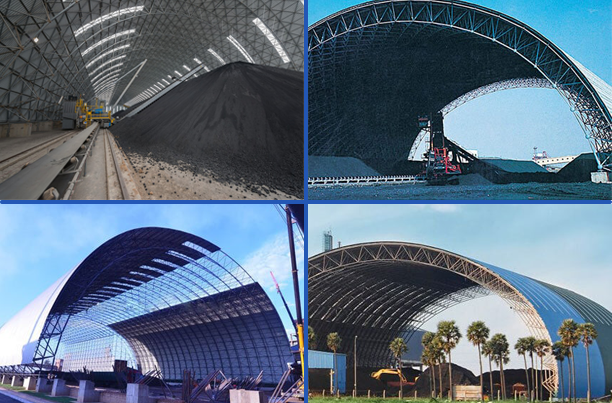

Multi-Storey Buildings

Steel frames construction is a very popular structural form for multi storey buildings as it provides great flexibility. The structure has adequate strength and stiffness to resist the applied loads due to gravity and wind. The function of the structure in resisting vertical loads due to gravity and horizontal loads due to wind is generally considered separately.

Learn More

Pre-Engineered Buildings

It offers a futuristic solution for creating durable and efficient structures in a cost-effective manner. Apart from great flexibility of designing and minimal construction time offered by PEB’s, they are also preferred for their robustness and durability. Moreover, it is possible to add a wide range of structural and non-structural components, which enhances their aesthetic appeal and also improves their usability.

Learn More

Membrane Structures

Textile supported by steel combines the high flexibility of use of this one, from reticular arches to infinite space geometries, with a singular covering applied only under optimum conditions in order to avoid abrasion and corrosion due to contact with the main bearing structure. The all-season use is guaranteed by a singular system of side opening in order to obtain maximum ventilation in the hot season.

Learn More

Self Supporting Roofs

A self-supporting roofing system makes it possible to erect a warehouse in one span without trusses, purlins, and rafters. The systems are mechanically sealed, which ensures better weather proofing and a hygienic and clean environment. The absence of holes, nuts, bolts, overlaps, or sealants, these structures require minimal to zero maintenance, making them highly cost-efficient.

Learn More

Suspended Facade Systems

In modern architecture and industrial construction, building facades have evolved much beyond simple external walls. Today, facade systems play a critical role in fire safety, thermal insulation, building performance, energy efficiency, durability, and architectural expression. Among the most advanced facade solutions used globally and in India, Suspended Facade Systems have gained significant importance.

Learn More