With over 20 years of experience, Hindustan Alcox is an industry leader in the fields of Engineering Procurement Construction (EPC) and heavy structure manufacturing.

Our team of designers and engineers have over 20 years of experience in airports, defence, multi-storey Buildings, Power, Cement and Steel Plant projects.

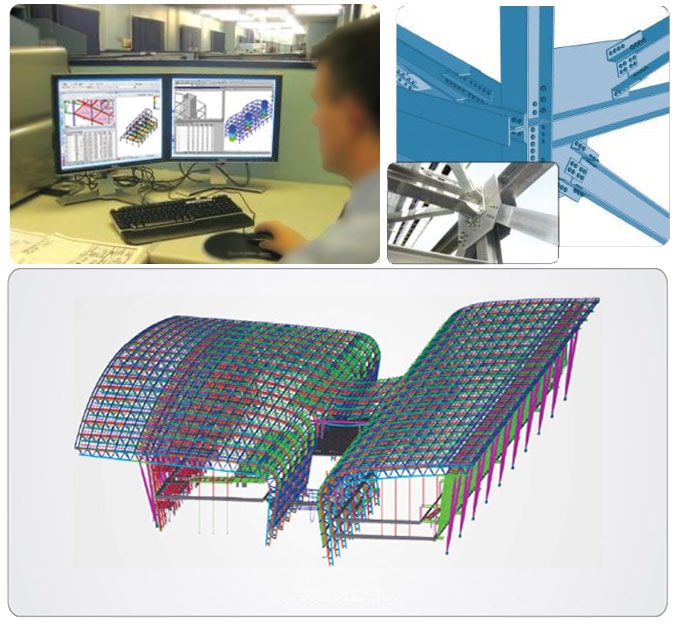

Our state-of-the-art fabrication facilities enable us to be global leaders in the design and production of large span steel structures, space frames and ETFE. The construction of Space Frames even of extraordinary geometric complexity has been made possible and by means of CAM system, the risk of human error is minimized and production process is totally reliable and safe.

Our production team utilises latest technology such as computerized plasma tube cutting and the CAD-CAM system to ensure consistent and reliable quality products.

Hindustan Alcox Ltd offers complete computer design information to architects and Engineers, as essential requisite in designing. Therefore, the most complex projects can be studied and analysed with accuracy.

The company is equipped with most advanced design softwares, and has built long term of cooperation relationship with various technology parters. It has a strong design and research ability.

With high experience in design and construction of specialised steel structures for various industries, we have undersigned many outstanding projects in domestic as well as international market.

The experts at Hindustan Alcox Ltd are updated with the latest technologies in the market, which allows them to take up designs of most complex structures.

The following records are always maintained to review/recheck for standards maintained in products.

Marerial Test Certificates, Manufacturing Test Certificates, Inspection Reports, Third Party Inspection Reports, Inspection Reparts of packing & Forwaring.

We have our own in house testing facilities & qualified engineers to conduct tests as per standards. The test for mechanical properties & chemical compositions are performed at Govt approved Laboratory.

The quality of materials, workmanship is maintained as per required standards by group of experienced, trained & skilled quality control engineers, technicians with precision measuring instruments & testing facilities. The quality is defined in very initial stage by following documentation methods.

Defines as procedures & norms of engineering. Procurement, manufacturing testing - acceptance norms, packing & forwarding & commission etc.

We have in house facilites with the qualified person for DA, MPI & UT. We take the services from outside approved laboratories for RT & mechanical properties testing.

The jobs manufactured / Process carried out by Alcox, has been inspected, withnessed & accepted by reputed. Third Party Inspection agencies, like Bureau Beritas.

Hindustan Alcox Ltd has an enviable track record of successful implementation of turnkey Structural Steel Projects at major Airports. It’s core competencies in Engineering include highly qualified and experienced personnel from various disciplines, state of an art 2D and 3D CAD/CAM facilities with sophisticated plant and machinery. We believe that our employees are the most important resource. They are associated with the growth of our organization. In order to provide them with the new skills, the company regularly conducts training programs for every employee to improve their performance & efficiency.

The company is committed to,

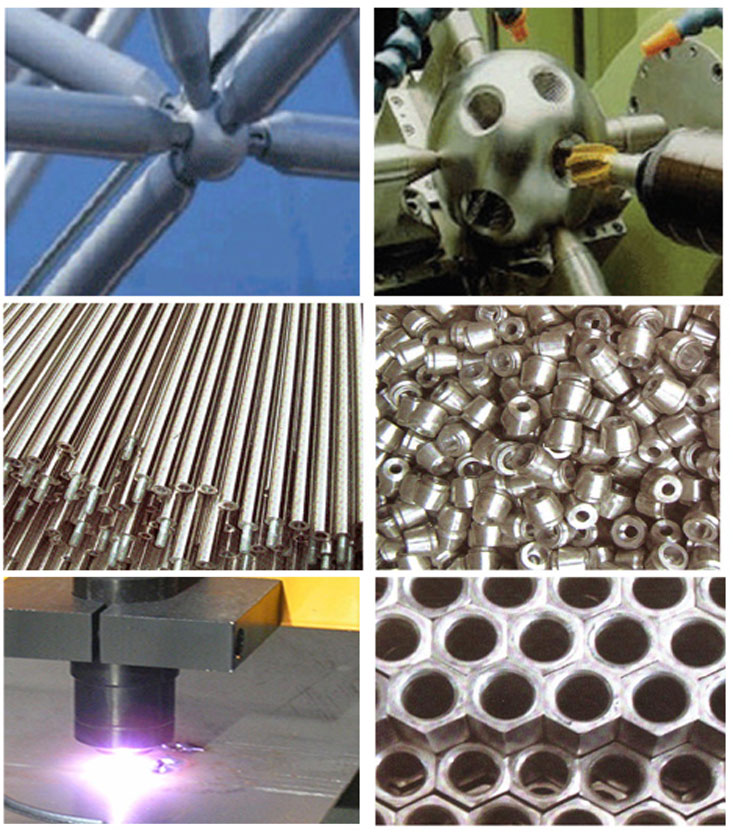

Hindustan Alcox Limited has put up its manufacturing facilities enable us with most modern equipments including computerized plasma tube cutting machine, Pipe bending machine and other welding, cutting machines etc.

The machining of spherical joints, cutting of tubes and welding of bars are carried out by high precision control computerized machines.

Thus, the construction of Space Frames even of extraordinary geometric complexity has been made possible and by means of CAM system, the risk of human error is minimized and production process is totally reliable and safe.

The integrated terminal buildings are designed with number of structural innovations. The key feature of airport structure is their long span roof covering with massive column spacing. The mega columns and large cantilevers make the structure unique. By using modular space frame structure supported by cantilevered columns makes the roof aesthetically good with doubly curved.

Go To Full PageIt offers a futuristic solution for creating durable and efficient structures in cost effective manner. Apart from great flexibility of designing and minimal construction time offered by PEB’s, they are also preferred for their robustness and durability. Moreover, it is possible to add a wide range of structural and non structural components, which enhances their aesthetic appeal and also improve their usability.

Go To Full PageSpace frame is a three dimensional structure. The 3D behavior ensures optimum utilization of material. The quality of roofing is exceptional good as the deflections are almost negligible. Despite their light weight, these structures are designed to carry much heavier load and have a huge spanning capacity. Erection time is minimal as the material is pre fabricated from the factory.

Go To Full PageSteel frames construction is a very popular structural form for multi storey buildings as it provides great flexibility. The structure has adequate strength and stiffness to resist the applied loads due to gravity and wind. The function of the structure in resisting vertical loads due to gravity and horizontal loads due to wind is generally considers separately.

Go To Full PageBulk storage sheds are large span structure to accommodate tons of coals for continuous supply to the boilers.The structures are designed with modular space frame to make it cost effective compared to other conventional structures. Catwalks, ducts and other services can be accommodated within the top and bottom chord.

Limestone Gypsum Additive Iron Ore CoalTextile supported by steel combines the high flexibility of use of this one, from reticular arches to infinite space geometries, with a singular covering applied only with optimum conditions in order to avoid abrasion and corrosion due to contact with main bearing structure. The all season use is guaranteed by a singular system of side opening in order to obtain maximum ventilation in hot season.

Go To Full PageSelf supporting roofing system makes it possible to erect a warehouse in one span without trusses, purlins and rafters. The systems are mechanically sealed which ensures better weather proofing and a hygienic and clean environment. The absence of holes, nuts, bolts, overlaps or sealants, these structures require minimal to zero maintenance making them highly cost efficient.

Go To Full PageTelephone: +91-11-65376653/54

Mobile: +91-9958646644 / +91-9818302640

Fax: +91-11-23588087

Email: info@alcox.in