Introduction

Bolted structures have become an integral part of modern construction, offering unparalleled advantages in terms of flexibility, strength, and ease of assembly. In particular, space frames—an advanced type of bolted structure—is gaining traction in architectural and industrial applications. This article delves into the world of bolted structure manufacturer in India, with a special focus on space frames.

What is a Bolted Structure?

Bolted structures are assemblies of components joined together using bolts. This method provides several benefits over welded structures, including ease of disassembly, flexibility in design, and reduced onsite labor.

Benefits over Welded Structures

Ease of Assembly and Disassembly: Bolted structures can be easily assembled and disassembled, making them ideal for temporary structures.

- Flexibility: They allow for modifications and expansions without major overhauls.

- Reduced Labour Costs: The construction process is faster and requires less specialized labour compared to welding.

Understanding Space Frames

Space frames are three-dimensional truss structures designed to withstand loads in various directions. Their geometric configuration distributes weight evenly, providing robust support and aesthetic appeal.

Advantages of Space Frames

- Lightweight: Despite their strength, space frames are relatively lightweight.

- Versatility: They can be used in a wide range of applications, from large stadiums to exhibition halls.

- Aesthetic Appeal: Space frames offer unique architectural possibilities, enhancing the visual impact of structures.

Bolted Structure Manufacturers in India

India’s bolted structure manufacturing industry is diverse and rapidly growing. Several leading manufacturers are known for their innovation, quality, and reliability.

Overview of the Industry

The industry includes companies specializing in designing, engineering, and manufacturing bolted structures for various applications. These manufacturers employ advanced technology and adhere to strict quality standards to ensure the durability and safety of their products.

Materials Used in Bolted Structures

The choice of materials is crucial for the performance and longevity of bolted structures.

Commonly Used Materials

- Steel: Offers high strength and durability.

- Aluminium: Lightweight and corrosion-resistant.

- Composite Materials: Provide enhanced performance characteristics.

Material Properties

Each material has specific properties that make it suitable for different applications. Steel, for example, is preferred for its load-bearing capacity, while aluminium is chosen for projects where weight is a critical factor.

Design & Engineering of Bolted Structures

Designing bolted structures involves meticulous planning and engineering to ensure stability and performance.

Design Principles

- Load Distribution: Ensuring even distribution of loads to prevent structural failure.

- Modularity: Designing components that can be easily assembled and disassembled.

Engineering Challenges

- Precision: Achieving precise alignment of components.

- Material Compatibility: Ensuring compatibility between different materials used in the structure.

Manufacturing Process

The manufacturing process of bolted structures involves several key steps, from raw material selection to final assembly.

Steps in the Manufacturing Process

- Design & Planning: Detailed design and planning to meet project specifications.

- Material Selection: Choosing the appropriate materials based on the application.

- Fabrication: Cutting, drilling, and shaping components.

- Assembly: Bolting components together as per the design.

Quality Control Measures

Strict quality control measures are implemented to ensure the structural integrity and performance of bolted structures. This includes material testing, inspection of components, and load testing.

Applications of Bolted Structures in Space Frames

Bolted structures, particularly space frames, are used in a variety of applications due to their versatility and strength.

Architectural Applications

- Stadiums: Providing large, open spaces without internal columns.

- Exhibition Halls: Offering flexibility in design and quick assembly.

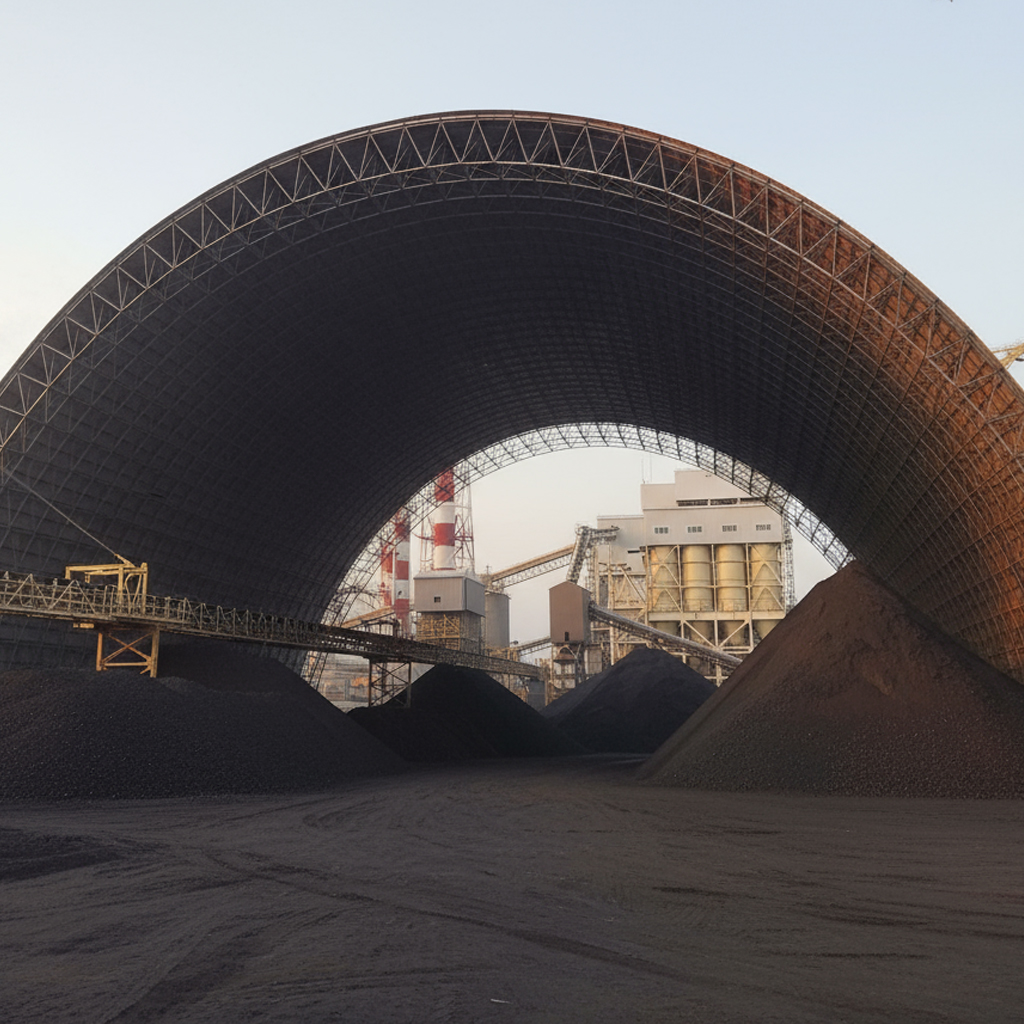

Industrial Applications

- Factories: Supporting heavy machinery and equipment.

- Warehouses: Providing large, unobstructed storage spaces.

Advantages of Using Bolted Structures in Space Frames

The use of bolted structures in space frames offers numerous advantages.

- Durability & Strength: Bolted structures are known for their durability and ability to withstand significant loads, making them ideal for large-scale constructions.

- Flexibility & Adaptability: They offer great flexibility, allowing for modifications and expansions as needed. This adaptability is particularly beneficial in dynamic environments where requirements may change over time.

Challenges in Manufacturing Bolted Structures

Despite their advantages, manufacturing bolted structures comes with its own set of challenges.

Technical Challenges

- Precision Engineering: Ensuring precise alignment and fit of components.

- Material Handling: Managing different materials and ensuring their compatibility.

Market Challenges

- Cost Competitiveness: Balancing quality with cost to remain competitive in the market.

- Regulatory Compliance: Adhering to stringent industry standards and regulations.

Innovations in Bolted Structure Manufacturing

The field of bolted structure manufacturing is continually evolving with new innovations.

Technological Advancements

- Automation: Use of automated machinery for precise fabrication and assembly.

- Advanced Materials: Development of new materials with superior properties.

Future Trends

- Sustainability: Increasing focus on sustainable materials and processes.

- Customization: Growing demand for customized solutions tailored to specific needs.

Environmental Impact of Bolted Structures

Bolted structures can have a significant environmental impact, both positive and negative.

Sustainability Considerations

- Recyclability: Many materials used in bolted structures are recyclable.

- Energy Efficiency: Efficient design can reduce energy consumption during construction.

Green Building Practices

- Use of Sustainable Materials: Incorporating eco-friendly materials.

- Minimizing Waste: Reducing waste through efficient design and manufacturing processes.

Conclusion

Bolted structures, particularly space frames, offer numerous advantages in modern construction. They provide durability, flexibility, and aesthetic appeal, making them suitable for a wide range of applications. The bolted structure manufacturing industry in India is robust, with several leading manufacturers driving innovation and quality. As the demand for sustainable and efficient construction solutions grows, bolted structures are set to play an increasingly important role in shaping the future of architecture and engineering.