Coal handling plants form an essential element of an efficient material flow and quality management process. An improved system integrated with all sub-systems efficiently deal with the steep demand of coal-fired plants to secure coal supply in sufficient quality and quantity. The infrastructure handles coal from receipt to their transfer to bunkers for boiler operations or stacking the coal to the coal yard. Primarily, there are three operating cycles of coal handling plants:

- Bunkering Cycle

- Stacking Cycle

- Reclaiming

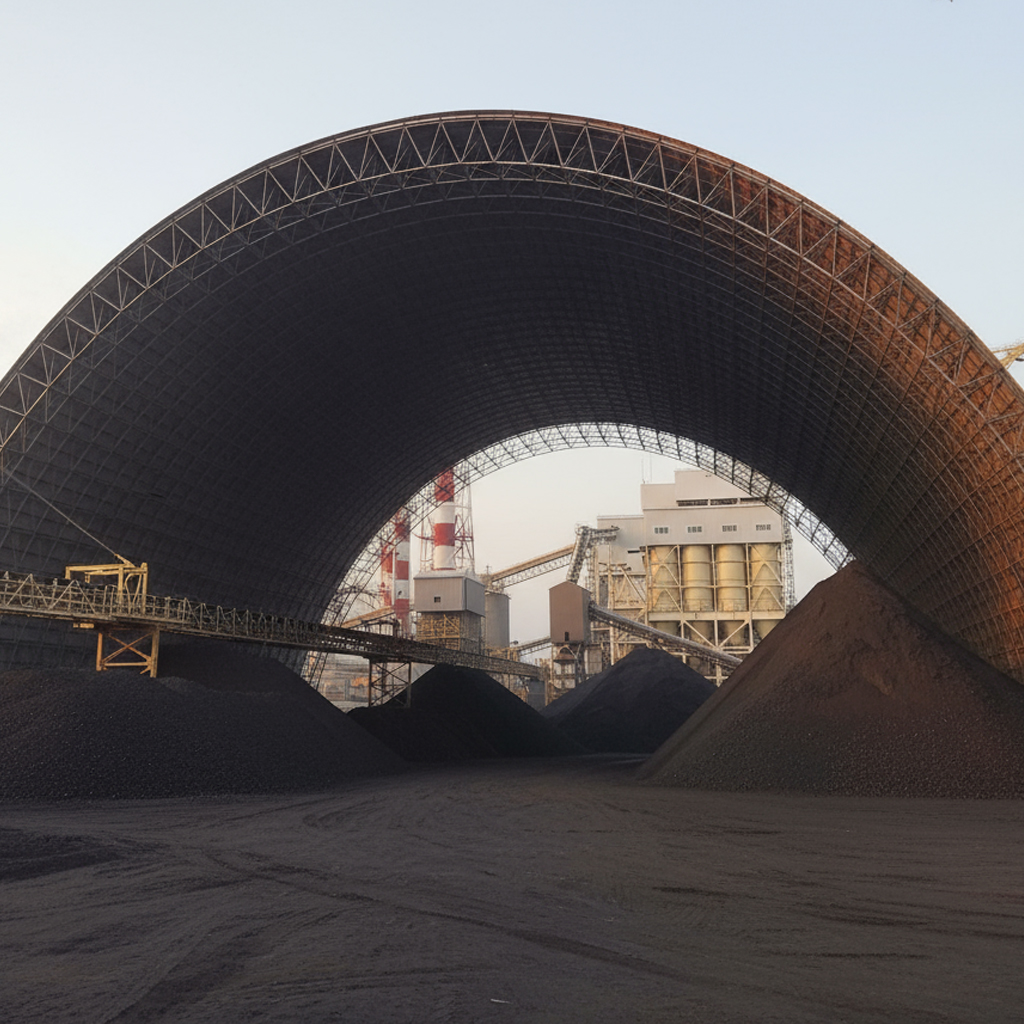

In addition to storage of bulk coal, Coal Storage Sheds address a wide array of areas on the industrial site including fuel and lubrication facilities, maintenance areas, washing areas and aggregate storage areas. Coal Storage Sheds are unique in design and yield higher space utilization for storage of coal. The greatest benefit of coal sheds is that they are economical, and these can be installed ensuring tandem operations of the yard.

These coal sheds can be built in lesser time compared to conventional structures and hence are suitable for mining and industrial projects. Energy efficiency and climate responsiveness play an important role in coal processing and storage.

Advantages

- Versatile architecture

- Greater clear spans

- Faster construction

- Lower maintenance cost

- Energy efficient roof structures do not require day time lighting facilities

- Efficient material consumption

We Hindustan Alcox Limited are the leading Coal storage shed manufacturer for over three decades. The engineering of our coal shed solutions promotes efficient space utilization for bulk material storage and freedom to stock material in multiple configurations.