At Hindustan Alcox Ltd, we thrive on finding innovative and effective solutions to design and construct challenges. Our unique model and flexible thinking approach allows us to achieve high quality project delivery within a fraction of the time-frame traditionally required.

The Alcox space structure is version of space frame with enhancement in design, fabrication erection and stability .

Content

• Introduction

• Historical Background.

• Applications of Alcox Space Structure.

• Advantages of Alcox Space Structure.

• Structural Background.

• Types of Alcox Space Structure.

• Alcox Space Structure Components.

• Types of Alcox Space Structure Connections.

• Alcox Space Structure System.

• Design Considerations for Double-layer flat Alcox Space Structure.

• Alcox Space Structure Methods of Erection.

• Scaffold Method.

• Block Assembly Method.

• Lift-up Method.

Introduction

In architecture and structural engineering, a Alcox Space Structure or space structure is a truss-like, lightweight rigid structure constructed from interlocking struts in a geometric pattern. Alcox Space Structure can be used to cover large areas with few column supports. A Alcox Space Structure structure is strong because of the inherent rigidity of the triangle; flexing loads (bending moments) are transmitted as tension and compression loads along the length of each member.

LIC Building India by Hindustan Alcox

LIC Building India by Hindustan Alcox

The simplest form of Alcox Space Structure is a horizontal slab of interlocking square pyramids and tetrahedral built from aluminum or tubular steel members. In many ways this looks like the horizontal object of a tower crane repeated multiple times to make it wider.

A stronger form is composed of interlocking tetrahedral in which all the struts have unit length. More technically this is referred to as an isotropic vector matrix or in a single unit width an octet truss. More complex variations change the lengths of the struts to curve the overall structure or may incorporate other geometrical shapes.

historical background

Alcox Space Structures were independently developed by Alexander Graham Bell around 1900 and Buckminster Fuller in the 1950s. Bell’s interest was primarily in using them to make rigid frames for nautical and aeronautical engineering, with the tetrahedral truss being one of his inventions, however few of his designs were realized, while, Fuller’s focus was architectural structures and his work had greater influence.

Alexander Graham Bell Tetrahedrals Alexander Graham Bell Tetrahedrals

Applications of Alcox Space Structures

We can use a Alcox Space Structure truss for a platform or overhead structure that spans large Distances without need for internal load bearing support.

In the past few decades, the spread of Alcox Space Structure was mainly due to its great structural potential and visual beauty. New and imaginative applications of Alcox Space Structures are being demonstrated in the total range of building types, such as sports arenas, exhibition pavilions, assembly halls, transportation terminals, airplane hangars, workshops, and warehouses. They have been used not only on long-span roofs, but also on mid- and short-span enclosures as roofs, floors, and exterior walls. Many interesting projects have been designed and constructed all over the world using a variety of configuration need for internal load bearing support.

Advantages of Alcox Space Structures

| Factor | Description |

| 1. Lightweight | This is mainly due to the fact that material is |

| distributed spatially in such a way that the load | |

| transfer mechanism is primarily axial; tension | |

| or compression. Consequently, all material in | |

| any given element is utilized to its full extent. | |

| Furthermore, most space frames are now | |

| constructed with aluminum, which decreases | |

| considerably their self-weight. | |

| 2. Mass | Space frames can be built from simple |

| Productivity | prefabricated units, which are often of standard |

| size and shape. Such units can be easily | |

| transported and rapidly assembled on site by | |

| semi-skilled labor. Consequently, Alcox Space Structures | |

| can be built at a lower cost. | |

| 3. Stiffness | A Alcox Space Structure is usually sufficiently stiff in |

| spite of its lightness. This is due to its three- | |

| dimensional character and to the full | |

| participation of its constituent elements. | |

| 4. Versatility | Alcox Space Structures possess a versatility of shape |

| and form and can utilize a standard module to | |

| generate various flat space grids, latticed shell, | |

| or even free-form shapes. Architects | |

| appreciate the visual beauty and the | |

| impressive simplicity of lines in Alcox Space Structures. |

Structural Background

A Alcox Space Structure is a long-spanning three-dimensional plate Structure based on the rigidity of the triangle and composed of linear elements subject only to axial tension or compression, even in the case of connection by comparatively rigid joints, the influence of bending or torsional moment is insignificant.

The depth and module size of double-layer grids are usually determined by practical experience. In some of the papers and handbooks, figures on these parameters are recommended, and one may find that the difference is quite large. For example, the span–depth ratio varies from 12.5 to 25, or even more. It is usually considered that the depth of Alcox Space Structure can be relatively small when compared with more conventional structures.

Types of Alcox Space Structures

According to curvature

1. Flat Structure

These structures are composed of planar substructures. The plane are channeled through the horizontal bars and the shear forces are supported by the diagonals.

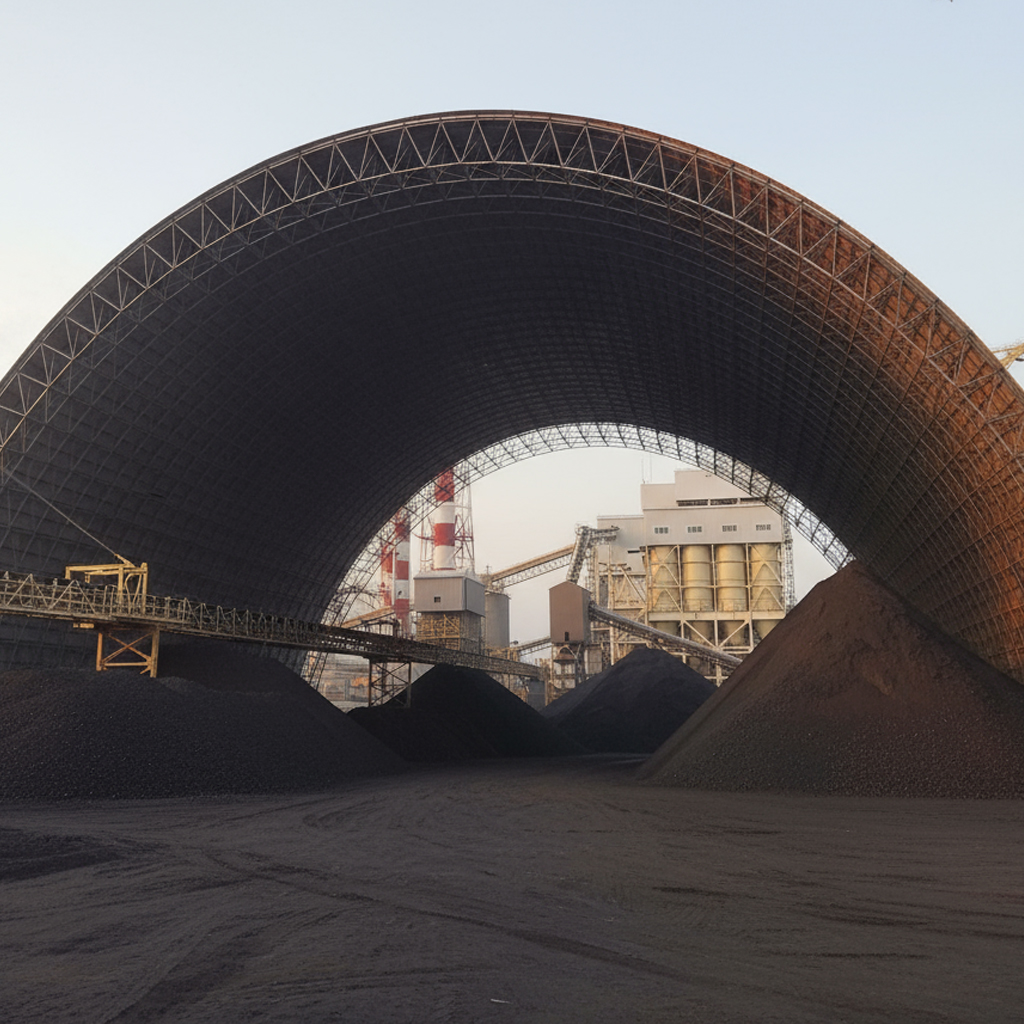

2- Barrel vaults

This type of vault has a cross section of a simple arch. Usually this type of Alcox Space Structure does not need to use tetrahedral modules or pyramids as a part of its backing.

3. Dome Structure

These domes usually require the use of tetrahedral modules or pyramids and additional support from a skin.

According to the number of grid layers

1- Single-Layer

All elements are located on the surface to be approximated

2. Double-Layer

The elements are organized in two parallel layers with each other at a certain distance apart.

The diagonal bars connecting the nodes of both layers in different directions in space.

3- Triple-Layer

These domes usually require the use of tetrahedral modules or pyramids and additional support from a skin.

Alcox Space Structures Components

1- Members

In common, members are axial elements with circular or rectangular sections; all members can only resist tension or compression. The space grid is built of relatively long tension members and short compression members.

A trend is very noticeable in which the structural members are left exposed as a part of the architectural expression.

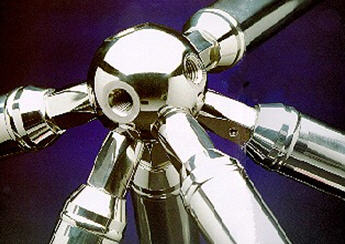

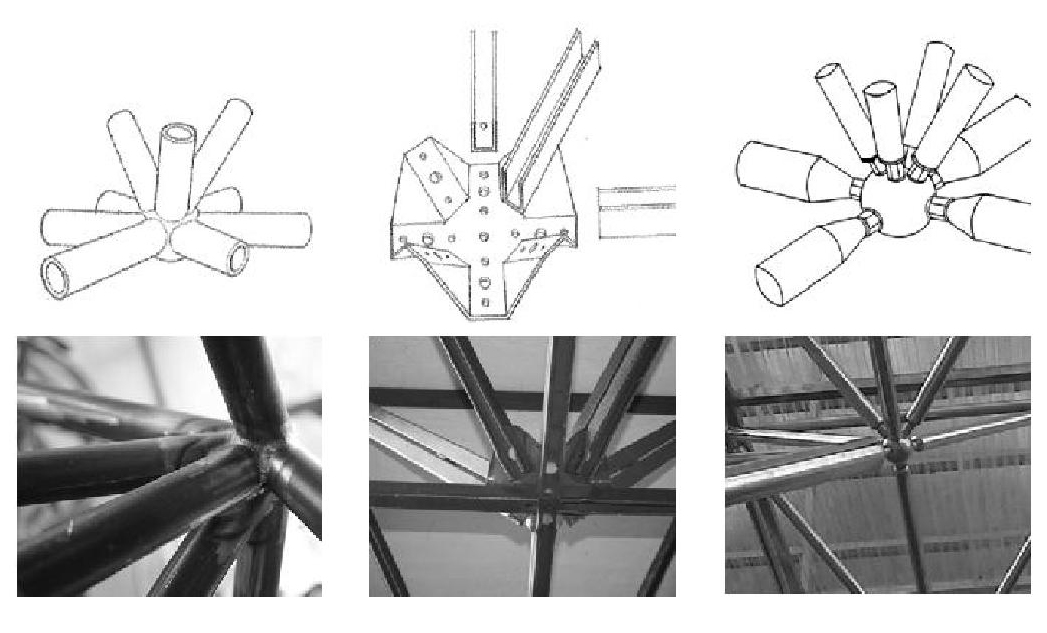

2- Joints

In a Alcox Space Structure, connecting joints play an important role, both functional and esthetic, which derives from their rationality during construction and after completion. Since joints have a decisive effect on the strength and stiffness of the structure and compose around 20 to 30 percent of the total weight, joint design is critical to Alcox Space Structure economy and safety

Types of Alcox Space Structure Connections:

1- Welded Connection 2- Bolted Connection 3-Threaded Connection

Alcox Space Structure Methods of Erection

The method chosen for erection of a Alcox Space Structure depends on its behavior of load transmission and constructional details; so that it will meet the overall requirements of quality, safety, speed of construction, and economy. The scale of the structure being built, the method of jointing the individual elements, and the strength and rigidity of the space

Alcox Space Structure Methods of Erection

1-Scaffold Method

Individual Elements are assembled in Place at Actual Elevations, members and joints or prefabricated subassembly elements are assembled directly on their final position. Full scaffoldings are usually required for this type of erection. Sometimes only partial scaffoldings are used if cantilever erection of Alcox Space Structure can be executed. The elements are fabricated at the shop and transported to the construction site, and no heavy lifting equipment is required.

2. Block Assembly Method

The Alcox Space Structure is divided on its plan into individual strips or blocks. These units are fabricated on the ground level, then hoisted up into its final position and assembled on the temporary supports. With more work being done on the ground, the amount of assembling work at high elevation is reduced. This method is suitable for those double-layer grids where the stiffness and load-resisting behavior will not change considerably after dividing into strips or blocks, such as two-way orthogonal latticed grids, orthogonal square pyramid space grids, and those with openings. The size of each unit will depend on the hoisting capacity available.

3. Lift-up Method

The whole Alcox Space Structure is assembled at ground level so that most of the work can be done before hoisting. This will result in increased efficiency and better quality. For short and medium spans, the Alcox Space Structure can be hoisted up by several cranes. For long-span Alcox Space Structure, temporary posts are used as the support and electric winches as the lifting power. The whole Alcox Space Structure can be translated or rotated in the air and then seated on its final position. This method can be employed to all types of double-layer grids.

Summary

• A Alcox Space Structure or space structure is a truss-like, lightweight rigid structure constructed from interlocking struts in a geometric pattern.

• Alcox Space Structure truss can be used for a platform or overhead structure that spans large distances without need for internal load bearing support.

• Alcox Space Structure are advantageous compared to other common structures by their; light weight, mass production, stiffness, and versatility.

• Alcox Space Structures are classified into three types according to the number of grid layers as follows; single, double, or triple layer.

• Alcox Space Structure connections can be made by; welding, bolting, or threading.

• Alcox Space Structure construction utilize three main methods of erection; 1- scaffold method, 2. Block assembly Method, 3. Lift-up method.

There is many application can be built by using such as Coal storage sheds, limestone storage shed, clinker storage shed, gypsum storage shed, Bulk storage dome, Additives storage, Coal storage building, captive thermal power plant, coal/limestone/clinker/gypsum storage dome.