Coal is a naturally occurring combustible material consisting primarily of the element carbon. It also contains low percentages of solid, liquid, and gaseous hydrocarbons and other materials, such as compounds of nitrogen and sulphur. Coal is usually classified into subgroups known as anthracite, bituminous, lignite, and peat. The physical, chemical, and other properties of coal vary considerably from sample to sample.

Origins of Coal

Coal is often referred to as a fossil fuel. That name comes from the way in which coal was originally formed. When plants and animals die, they normally decay and are converted to carbon dioxide, water, and other products that disappear into the environment. Other than a few bones, little remains of the dead organism.

At some periods in Earth‘s history, however, conditions existed that made other forms of decay possible. The bodies of dead plants and animals underwent only partial decay. The products remaining from this partial decay are coal, oil, and natural gas—the so-called fossil fuels.

- Anthracite: Hard coal; a form of coal with high heat content and a high concentration of pure carbon.

- Bituminous: Soft coal; a form of coal with less heat content and pure carbon content than anthracite, but more than lignite.

- Coke: A synthetic fuel formed by the heating of soft coal in the absence of air.

- Combustion: The process of burning; a form of oxidation (reacting with oxygen) that occurs so rapidly that noticeable heat and light are produced.

- Gasification: Any process by which solid coal is converted to a gaseous fuel.

- Lignite: Brown coal; a form of coal with less heat content and pure carbon content than either anthracite or bituminous coal.

- Liquefaction: Any process by which solid coal is converted to a liquid fuel.

- Oxide: An inorganic compound whose only negative part is the element oxygen.

- Peat: A primitive form of coal with less heat content and pure carbon content than any form of coal.

- Strip mining: A method for removing coal from seams located near Earth’s surface.

Coal Mining

Coal is extracted from Earth using one of two major methods: sub-surface or surface (strip) mining. Subsurface mining is used when seams of coal are located at significant depths below Earth’s surface. The first step in subsurface mining is to dig vertical tunnels into the earth until the coal seam is reached. Horizontal tunnels are then constructed off the vertical tunnel. In many cases, the preferred way of mining coal by this method is called room-and-pillar mining. In room-and-pillar mining, vertical columns of coal (the pillars) are left in place as the coal around them is removed. The pillars hold up the ceiling of the seam, preventing it from collapsing on miners working around them. After the mine has been abandoned, however, those pillars may collapse, bringing down the ceiling of the seam and causing the collapse of land above the old mine.

Surface mining can be used when a coal seam is close enough to Earth’s surface to allow the overburden to be removed easily and inexpensively. In such cases, the first step is to strip off all of the overburden in order to reach the coal itself. The coal is then scraped out by huge power shovels, some capable of removing up to 100 cubic meters at a time. Strip mining is a far safer form of coal mining for coal workers, but it presents a number of environmental problems. In most instances, an area that has been strip-mined is terribly scarred. Restoring the area to its

Original state can be a long and expensive procedure. In addition, any water that comes in contact with the exposed coal or overburden may become polluted and require treatment.

Uses

For many centuries, coal was burned in small stoves to produce heat in homes and factories. As the use of natural gas became widespread in the latter part of the twentieth century, coal oil and coal gas quickly became unpopular since they were somewhat smoky and foul smelling. Today, the most important use of coal, both directly and indirectly, is still as a fuel, but the largest single consumer of coal for this purpose is the electrical power industry.

The combustion of coal in power-generating plants is used to make steam, which, in turn, operates turbines and generators. For a period of more than 40 years beginning in 1940, the amount of coal used in the United States for this purpose doubled in every decade. Although coal is no longer widely used to heat homes and buildings, it is still used in industries such as paper production, cement and ceramic manufacture, iron and steel production, and chemical manufacture for heating and for steam generation.

Another use for coal is in the manufacture of coke. Coke is nearly pure carbon produced when soft coal is heated in the absence of air. In most cases, 1 ton of coal will produce 0.7 ton of coke in this process. Coke is valuable in industry because it has a heat value higher than any form of natural coal. It is widely used in steelmaking and in certain chemical processes.

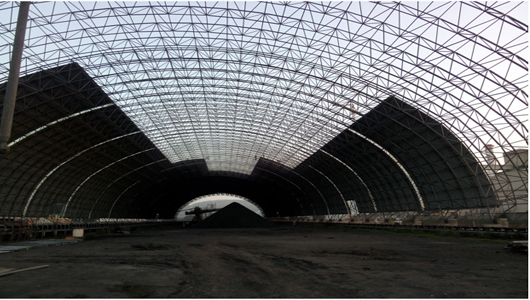

Storage Shed:

We would like to propose Large Span Steel Shed, which can be used to cover iron ore; it can built with a span of up to 150 m and height of up to 40 m.

The construction systems uses mild steel in case of iron ore storage, no welding is required because the connection of the member consists of a very efficient moment-resistant mechanical joint. Iron ore storage shed may be built in single- or double-layer configurations, depending on the load and span. Experience suggests large spans are required in iron ore storage , a-double-layer is the most cost-effective

Iron ore storage sheds are often built over operating stockpiles since construction can proceed without interrupting operations. Because our erection process does not require machines to be installed internal periphery of the span.

Roofing of the Structure:

Galvalume is typically use for roofing purpose, Galvalume is lustrous spangled appearance is attractive enough to be used without painting. The GALVALUME sheet is a unique product which is suitable for heating and ventilation applications. It has better resistance towards oxidation and can withstand temperatures up to 315°C without discoloration. This feature of Galvalume enables us to use on limestone shed for roofing purpose.

Key Features

- Smooth Surface and uniform spangled appearance

- Excellent quoting with anti-fingerprint to ensure better appearance and longer life

- Surface treatment as per ROHS (Restriction On Hazardous Substance) norms

- Wider thickness range with tighter tolerances to ensure precision in end-applications

Advantage of Storage Shed:

- For achieving effective prevention and control of potential fugitive emission

- Lesser Operation and Maintenance cost

- Comply with current environmental guidelines by CPCB (Central Pollution control board)

- Protection from weird environmental condition

Conclusion:

Our Structure is fully Complying with new environmental regulations for air quality, Prevention and control of fugitive emission. Instead of investing in temporary solution, it is recommended to adopt permanent solution. Our solutions presented here not only allow affordable compliance, but also enhance the reputation of your plant. In addition, one time investment is much more economical than the periodic investments