Understanding Bulk Storage Warehouses

Bulk storage warehouses play a pivotal role in supply chain management, acting as centralized hubs for storing large quantities of raw materials or finished goods. These facilities prioritize efficiency, safety, and scalability to support industries ranging from agriculture to manufacturing.

Definition of Bulk Storage Warehouses

- Key Characteristics: A bulk storage warehouse is a specialized facility designed to store goods in large quantities, typically without individual packaging. Features like reinforced flooring, high ceilings, and customizable layouts distinguish these structures.

- Importance in Supply Chain Management: Bulk storage ensures a steady supply of goods, minimizing disruptions. As logistics expert Peter Drucker aptly stated, “Efficiency is doing things right; effectiveness is doing the right things.”

Types of Bulk Storage

- Open Storage: Open storage refers to outdoor facilities, ideal for goods resistant to weather, such as construction materials.

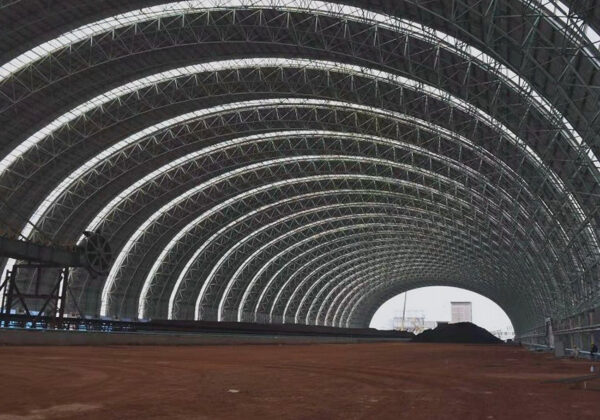

- Covered Storage: Covered storage offers partial protection, often using canopies or temporary structures for goods like grains or fertilizers.

- Climate-Controlled Storage: This advanced type ensures regulated temperatures and humidity levels, vital for perishable or sensitive goods.

Key Features of Bulk Storage Warehouses

Structural Design Considerations

- Load-Bearing Capacity: The design of bulk storage warehouses includes reinforced structures to handle heavy loads, preventing structural damage.

- Space Optimization: Efficient layout planning ensures maximum utilization of space, accommodating a variety of goods.

Material Handling Systems

- Conveyors & Stackers: Automated conveyors and stackers streamline the movement of bulk materials, reducing manual labor and time.

- Automated Storage & Retrieval Systems (ASRS): ASRS integrates robotics for precise handling, enhancing operational accuracy.

Ventilation & Climate Control

- Humidity & Temperature Regulation: Modern warehouses deploy HVAC systems to maintain ideal conditions for stored goods.

- Preventing Contamination: Effective ventilation prevents contamination from dust, pests, or moisture.

Materials Stored in Bulk Warehouses

- Agricultural Products: Grains, pulses, and fertilizers are stored in bulk to ensure consistent supply and quality.

- Industrial Raw Materials: Items like coal, sand, and chemicals are commonly stored in bulk warehouses, often requiring specialized handling.

- Finished Goods & Equipment: Large machinery and packaged products are stored in bulk warehouses before distribution.

Challenges in Bulk Storage

- Efficient Space Utilization: Optimizing storage layout for diverse goods is a critical challenge.

- Inventory Management Systems: Manual tracking can lead to inaccuracies; hence, sophisticated inventory systems are a necessity.

- Ensuring Safety & Compliance: Adherence to safety regulations and fire codes is essential for preventing accidents and ensuring operational legality.

Technological Advancements in Bulk Storage Warehouses

- Internet of Things (IoT) Applications: IoT sensors monitor inventory levels and environmental conditions in real-time.

- AI & Machine Learning for Inventory Optimization: AI-driven analytics predict demand, reducing overstock and under stock scenarios.

- Smart Sensors & Automation: Smart systems alert operators to irregularities, ensuring immediate corrective actions.

Benefits of Bulk Storage Warehouses

- Cost Efficiency in Logistics: Bulk storage reduces transportation costs by consolidating goods at centralized locations.

- Scalability & Flexibility: The modular design allows warehouses to adapt to changing storage needs.

- Enhanced Operational Efficiency: Automation and advanced systems optimize workflows, saving time and resources.

Conclusion

Bulk storage warehouses are indispensable in modern logistics, offering a reliable solution for managing large quantities of goods. Their integration of advanced technologies and efficient designs ensures they meet the growing demands of global industries.