Introduction

Limestone plays a vital role in many industries, from cement manufacturing to construction. As a key raw material, the proper storage and handling of limestone are crucial for maintaining its quality and ensuring uninterrupted operations in industrial settings. One of the best solutions for this is the limestone stockpile sheds. These sheds serve as storage structures designed to protect limestone from external environmental factors and ensure smooth material handling processes.

Overview of Limestone & Its Applications

- Industrial Use of Limestone: Limestone is widely used in industries such as cement production, steel manufacturing, and construction. Its high calcium content makes it an essential raw material for producing lime, which is a critical component in making steel and cement. Additionally, limestone is used in agriculture to neutralize acidic soils, improving crop productivity.

- Significance of Limestone in Construction & Manufacturing: In the construction industry, limestone is often used as a building material for its strength and durability. It’s also used as an aggregate in concrete mixes. In manufacturing, limestone’s high calcium carbonate content makes it ideal for use in various chemical processes, from producing glass to treating wastewater.

What is a Limestone Stockpile Shed?

Definition & Purpose: A limestone stockpile shed is a large, often custom-designed structure used to store large volumes of limestone. The purpose of these sheds is to protect the limestone from weather conditions such as rain, snow, and excessive heat, which could affect its quality. They also help manage dust and other environmental concerns by containing the material in a controlled environment.

Key Features of Stockpile Shed for Limestone

- Weather Protection: The shed protects limestone from moisture, which can cause degradation or unwanted chemical reactions.

- Dust Control: Limestone is prone to creating dust, and stockpile sheds are designed to minimize dust pollution.

- Durability: These sheds are typically built to withstand heavy loads and extreme weather conditions, ensuring longevity and reliability.

Types of Limestone Stockpile Sheds

- Open Sheds vs. Enclosed Sheds: Limestone stockpile sheds come in two main varieties: open and enclosed. Open sheds are less expensive and offer easy access to materials but provides limited protection from weather elements. Enclosed sheds, on the other hand, offer full protection and are ideal for environments where material quality and environmental factors are crucial.

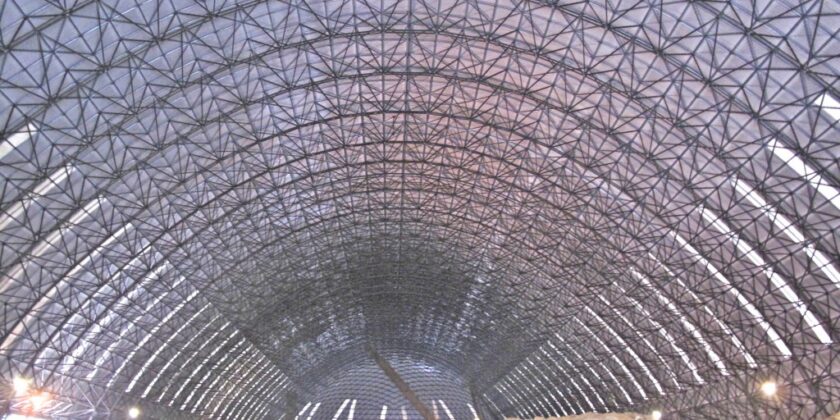

- Dome Shaped Stockpile Sheds: Dome-shaped sheds are popular in the industry due to their structural efficiency and space optimization. The circular design allows for even distribution of materials and minimizes the amount of space wasted. Dome sheds also offer excellent resistance to wind and weather-related wear.

- Rectangular Stockpile Sheds: Rectangular sheds are the most traditional form and are often used when space is less of a concern. These sheds are ideal for storing materials in organized rows and allow for the integration of conveyor belts and other material-handling systems.

Design Considerations for Limestone Stockpile Sheds

- Structural Requirements: When designing a limestone stockpile shed, structural integrity is paramount. The building needs to withstand the weight of stored materials and be durable enough to last for decades. High-quality materials like steel are often used for constructing the shed’s framework, ensuring long-term stability.

- Weather Resistance & Ventilation: Limestone sheds must offer protection from moisture and extreme temperatures. Adequate ventilation is also critical, as poor airflow can lead to condensation, potentially compromising limestone quality. Ventilation systems should be strategically placed to ensure proper airflow throughout the shed.

- Environmental Impact & Sustainability: Modern limestone stockpile sheds are designed with environmental sustainability in mind. Energy-efficient construction techniques, the use of recyclable materials, and dust control mechanisms help reduce the environmental impact. Additionally, some sheds are built to capture rainwater, which can be used in industrial processes, further enhancing sustainability.

Importance of Limestone Stockpile Sheds in Cement Manufacturing

- Ensuring Material Quality: For the cement industry, maintaining the quality of limestone is crucial. Stockpile sheds ensure that the limestone is kept in optimal conditions, preventing contamination from dust, moisture, and other elements. These results in higher-quality cement production and more consistent material properties.

- Managing Dust & Environmental Concerns: Dust control is a significant concern in limestone handling. Limestone stockpile sheds are often equipped with dust suppression systems that prevent fine particles from becoming airborne, which is both an environmental hazard and a health risk for workers. Proper dust management also helps in maintaining compliance with environmental regulations.

Material Handling & Storage Efficiency

- Bulk Material Handling Solutions: Limestone stockpile sheds are typically equipped with bulk material handling systems, such as conveyor belts, to efficiently transport the material from storage to processing facilities. These systems are designed to minimize material degradation and optimize the flow of limestone throughout the facility.

- Conveyor Systems in Limestone Sheds: Conveyor systems play an essential role in material handling within limestone stockpile sheds. These systems automate the movement of materials, improving efficiency and reducing the need for manual labor. Some advanced conveyor systems are also equipped with sensors and automated control systems to monitor the flow of materials in real-time.

- Automation & Smart Storage Solutions: The future of limestone stockpile sheds lies in automation and smart storage solutions. Advanced systems that use sensors, drones, and AI-driven software allow facilities to monitor the quantity and quality of stored materials in real-time, enabling more efficient operations.

Maintenance & Durability of Limestone Stockpile Sheds

- Regular Inspections: Maintaining the integrity of a limestone stockpile shed requires regular inspections. These inspections ensure that the shed’s structure remains sound, and no leaks or weaknesses are compromising the storage environment.

- Common Repairs & Upkeep: Over time, wear and tear is inevitable. Common repairs might include patching holes in the roof, reinforcing structural beams, and replacing sections of the conveyor system. Regular maintenance helps prolong the lifespan of the shed and ensures it continues to function effectively.

Conclusion

Limestone stockpile sheds are essential for industries that rely on bulk limestone storage. These sheds not only protect the material from environmental factors but also improve the efficiency of material handling and processing. With advances in automation and smart technologies, the future of limestone stockpile sheds promises even greater efficiency, sustainability, and durability.