Role of Gypsum in Cement Industry:

Limestone, gypsum, slag & other additives are the most common raw materials used in cement production. Gypsum is a soft, transparent or translucent mineral composed of crystallised calcium sulphate (CaSO4), found naturally in sedimentary deposits. Gypsum is added to cement to regulate the extreme setting reaction which occurs in the presence of water. Besides influencing the setting time, gypsum also has an influence on other properties of cement such as strength development, volume stability etc.

Flue Gas De-Sulphurized (FGD) Gypsum (An Important By-Product of Cement industry):

FGD gypsum results from the emissions cleaning process known as flue gas de-sulphurisation (FGD), at coal fired electricity generating stations. The cleaning of flue gases is carried out when finely ground limestone (or lime) reacts with sulphur dioxide emissions to produce a pure gypsum. In some cement industries, a multistep manufacturing process with electric utilities are carried out to meet precise product specifications for FGD gypsum. Followings are the importance of FGD gypsum, as by-product of cement industry:

- Contribution as an end product

- Environment Friendly

- Highly Economic

- Higher Purity Than Natural resources

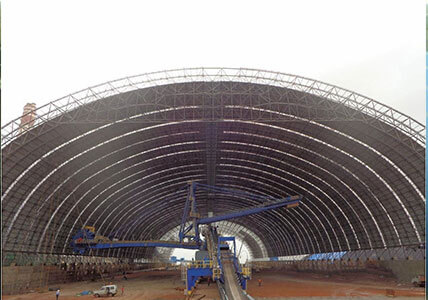

Hindustan Alcox Limited take pride to be one of the top gypsum storage shed manufacturer in India by offering world-class sheds in form of barrel vault structural sheds or gypsum domes. The Company has wide experience of about 30 years in building FGD sheds with long span steel structure having span of up to 150 m & height of up to 40 m.