Production in Cement Plant-

Cement is a basic building material produce by cement plants. Creation of cement goes through some crucial steps with each step involving creation of intermediate compounds and finally produces cement. There are many types of storage such as limestone storage, coal storage, iron ore storage and many more.

The first foremost step in cement manufacturing process is calcinations of Calcium Carbonate (CaCo3), which can easily available in form of Naturally occurring calcareous deposits such as limestone, marl or chalk. The Calcinations of Calcium Carbonate produces Calcium Oxide as intermediate compound for the next step.

In the Second Step, the produced calcium oxide is burn with silica, alumina, ferrous compounds and others & produces another intermediate compound known as clinker. The clinker storage can be kept as open or closed (under clinker storage shed) type. The nodules of cement clinker are then grinded with other additives like gypsum to the consistency of face powder to produce powdered cement.

More than adequate amount of raw materials are required to produce adequate amount of clinker along with the energy consumption in form of heat. From the above procedure involved in the manufacturing of best quality cement, we need to:

- Preserve the resources from getting degraded

- Bear losses in form of waste produced during intermediate processes

- Preserve the resources like petcoke, coal required to produce heating effect

- Uplift or Maintain brand quality by producing best quality of cement

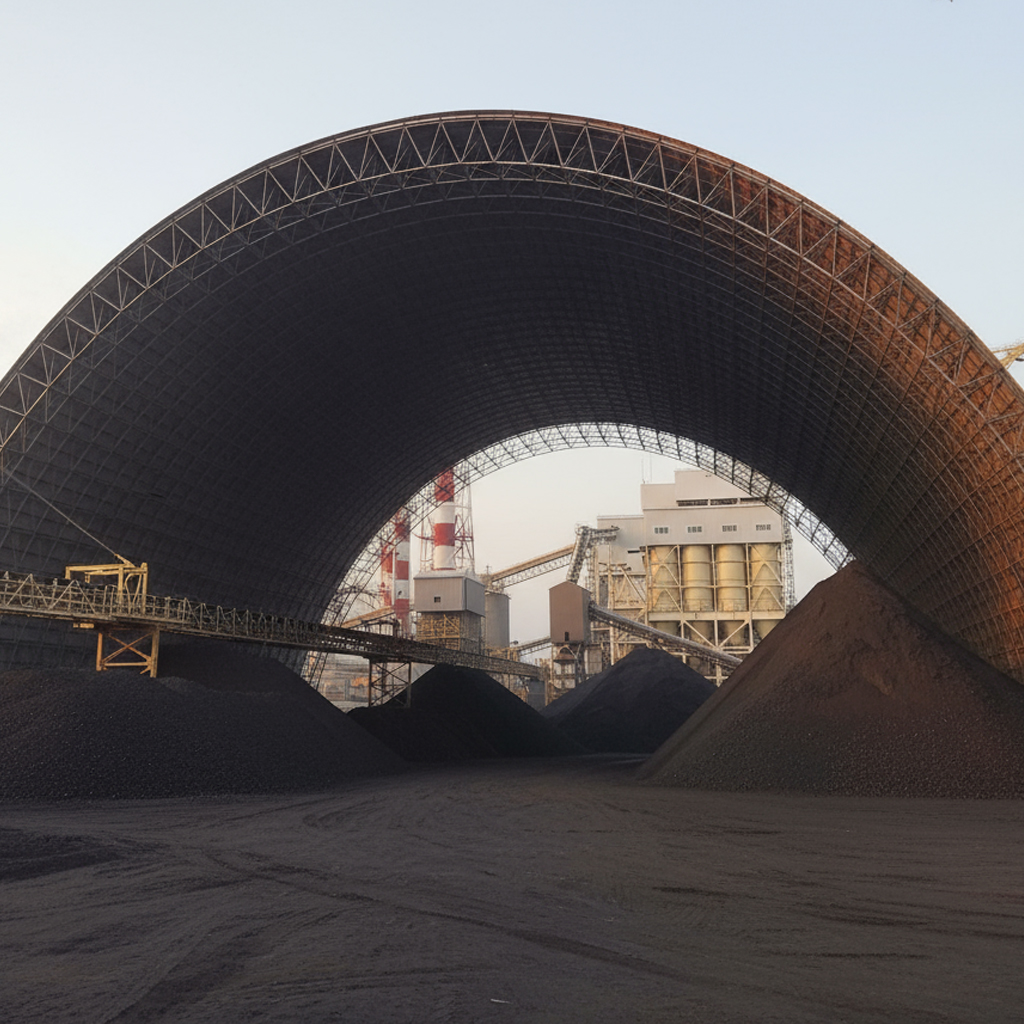

Why Clinker or Limestone Storage Sheds?

Many cement plants have adopted primary measures such as optimized process control, use of modern fuel feed systems, adequate cooler connections & power management systems, to avoid all such dangers. However, those primary measures are not sufficient to improve cement production in any cement plant.

In order to get rid of all the above-mentioned liabilities, it is the key responsibility of owner of cement plant to leave no flaw in producing best quality cement and sustain its brand value in the market, which can be accomplished by using Clinker or Limestone Storage Sheds over cement plants under operation.

Hindustan Alcox Limited specializes in providing storage solution for limestone with long span steel structure having span of up to 150 m & height of up to 40 m. Limestone storage shed, engineered by the company is the best choice to cover stockpile for the most challenging environment. In cement plants, Clinker storage sheds or Limestone storage sheds are often built over operating stockpiles so that construction may proceed without interrupting operations.