Industrial sheds have undergone significant transformations over the years. The integration of space frame structures marks a remarkable advancement in architectural and engineering domains. In this article, we’ll delve into the world of industrial sheds, focusing on how space frames revolutionize their design and functionality. We’ll explore the benefits, applications, construction methods of using space frames in industrial sheds.

Understanding Space Frame Structures

A space frame is a truss-like, lightweight rigid structure constructed from interlocking struts in a geometric pattern. It derives its strength from the triangular frames, which distribute loads in multiple directions. This structural form is known for its high strength-to-weight ratio, allowing for expansive spaces without internal columns, making it ideal for industrial sheds.

Benefits of Space Frame Structures in Industrial Sheds

- Enhanced Load Distribution: One of the primary benefits of space frame structures is their ability to distribute loads efficiently. The interconnected struts create a three-dimensional force distribution, which enhances stability and reduces stress concentrations. This characteristic is particularly advantageous for industrial sheds that house heavy machinery or materials.

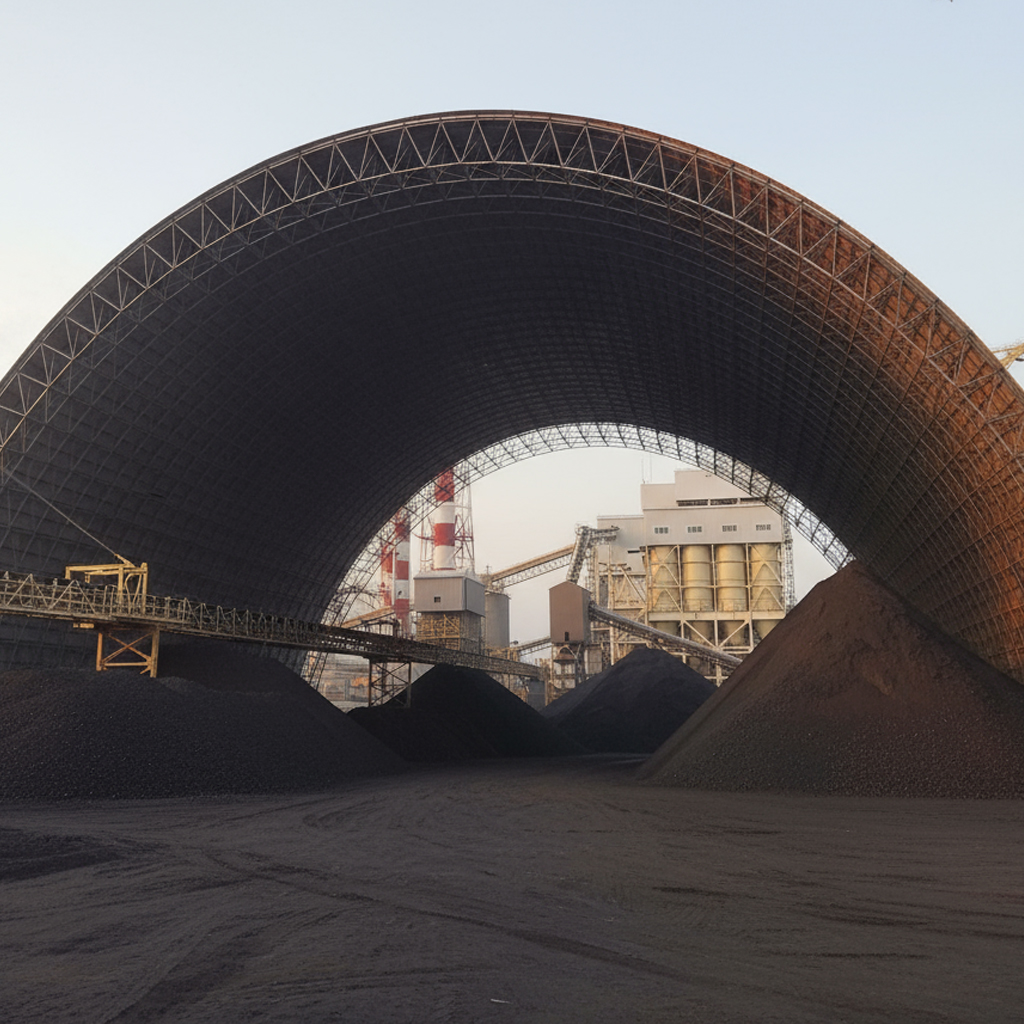

- Large Clear Spans: Space frames enable the construction of large clear spans, eliminating the need for internal columns. This creates unobstructed floor space, essential for various industrial operations such as manufacturing, warehousing, and assembly lines. The flexibility in space usage enhances workflow efficiency and adaptability.

- Lightweight and Durable: Despite their robust structural integrity, space frames are relatively lightweight. This weight reduction translates into lower foundation costs and easier transportation and installation processes. Additionally, the materials used in space frames, such as steel and aluminium, are highly durable and resistant to environmental factors, ensuring longevity and minimal maintenance.

- Aesthetic Appeal: Space frame structures offer a modern and visually appealing aesthetic. The geometric patterns and sleek lines add an element of sophistication to industrial sheds, making them not only functional but also architecturally pleasing. This can be a significant advantage for companies looking to enhance their brand image.

- Versatile Design: The modular nature of space frames allows for versatile design options. They can be easily customized to fit specific architectural and operational requirements. Whether it’s a simple rectangular shed or a complex multi-faceted structure, space frames provide the flexibility to achieve the desired design without compromising on structural integrity.

Applications of Space Frame Structures in Industrial Sheds

- Warehousing & Storage Facilities: The expansive clear spans offered by space frames make them ideal for warehousing and storage facilities. The unobstructed space allows for efficient use of storage systems, easy movement of goods, and optimal layout of shelving units.

- Manufacturing Plants: Industrial sheds housing manufacturing plants benefit from the open floor plan provided by space frames. This facilitates the installation of production lines, heavy machinery, and equipment, enhancing the overall efficiency of manufacturing processes.

- Agricultural Buildings: Agricultural buildings such as barns and greenhouses benefit from the lightweight and durable nature of space frames. The ability to cover large areas without internal supports is particularly advantageous for these applications.

Construction Methods of Space Frame Structures

- Prefabrication: One of the key construction methods for space frame structures is prefabrication. The individual components are manufactured off-site in a controlled environment and then transported to the construction site for assembly. This method ensures precision and quality control, reduces construction time, and minimizes on-site labor.

- On-Site Assembly: On-site assembly involves the construction of space frame structures directly at the site. While this method may require more time and labor, it offers flexibility in making adjustments during the construction process. This can be beneficial for projects with unique or changing requirements.

- Modular Construction: Modular construction combines the advantages of prefabrication and on-site assembly. Modules or sections of the space frame are prefabricated and then assembled on-site. This method enhances construction speed and efficiency while maintaining flexibility in design and adjustments.

- Welding & Bolting Techniques: The connections in space frame structures are crucial for their integrity. Welding and bolting techniques are commonly used to join the struts. Welding provides a permanent and robust connection, while bolting allows for disassembly and reassembly, offering flexibility for future modifications or relocation.

Challenges & Considerations

- Initial Costs: While space frame structures offer numerous benefits, the initial costs can be higher compared to traditional construction methods. However, the long-term savings in maintenance, energy efficiency, and operational flexibility often offset these initial investments.

- Skilled Labour Requirements: The construction of space frame structures requires skilled labor, particularly in welding and assembly techniques. Ensuring that the workforce is adequately trained is essential for the successful implementation of these structures.

- Design & Engineering Complexity: The design and engineering of space frame structures can be complex, requiring specialized knowledge and expertise. Collaboration with experienced architects and engineers is crucial to achieving the desired outcomes and ensuring structural integrity.

Conclusion

The incorporation of space frame structures in industrial sheds marks a significant advancement in the construction industry. With their superior load distribution, large clear spans, lightweight nature, and aesthetic appeal, space frames offer a multitude of benefits for various industrial applications. As the demand for sustainable, flexible, and technologically advanced construction continues to rise, space frame structures are poised to play a pivotal role in shaping the future of industrial architecture. By embracing these innovative structures, industries can enhance their operational efficiency, adapt to changing needs, and contribute to a more sustainable built environment.