Understanding Bulk Cement Storage

What is Bulk Cement Storage?

- Definition and Importance: Bulk cement storage refers to the systematic storage of cement in large quantities, typically in silos, warehouses, or specialized containers. This storage method ensures the material remains dry and free from contamination, which is essential for maintaining its integrity and usability in construction.

- Industries Utilizing Bulk Cement: Industries such as construction, infrastructure development, and precast manufacturing rely heavily on bulk cement storage. Large-scale projects demand consistent and efficient access to cement, making bulk storage indispensable.

Benefits of Storing Cement in Bulk

- Cost-Efficiency: Storing cement in bulk reduces packaging and transportation costs. It also minimizes waste by protecting the material from spillage and spoilage.

- Environmental Impact: Bulk storage reduces the reliance on single-use packaging materials, contributing to more sustainable construction practices.

- Quality Preservation: Proper storage conditions protect cement from moisture and contaminants, ensuring its performance remain consistent over time.

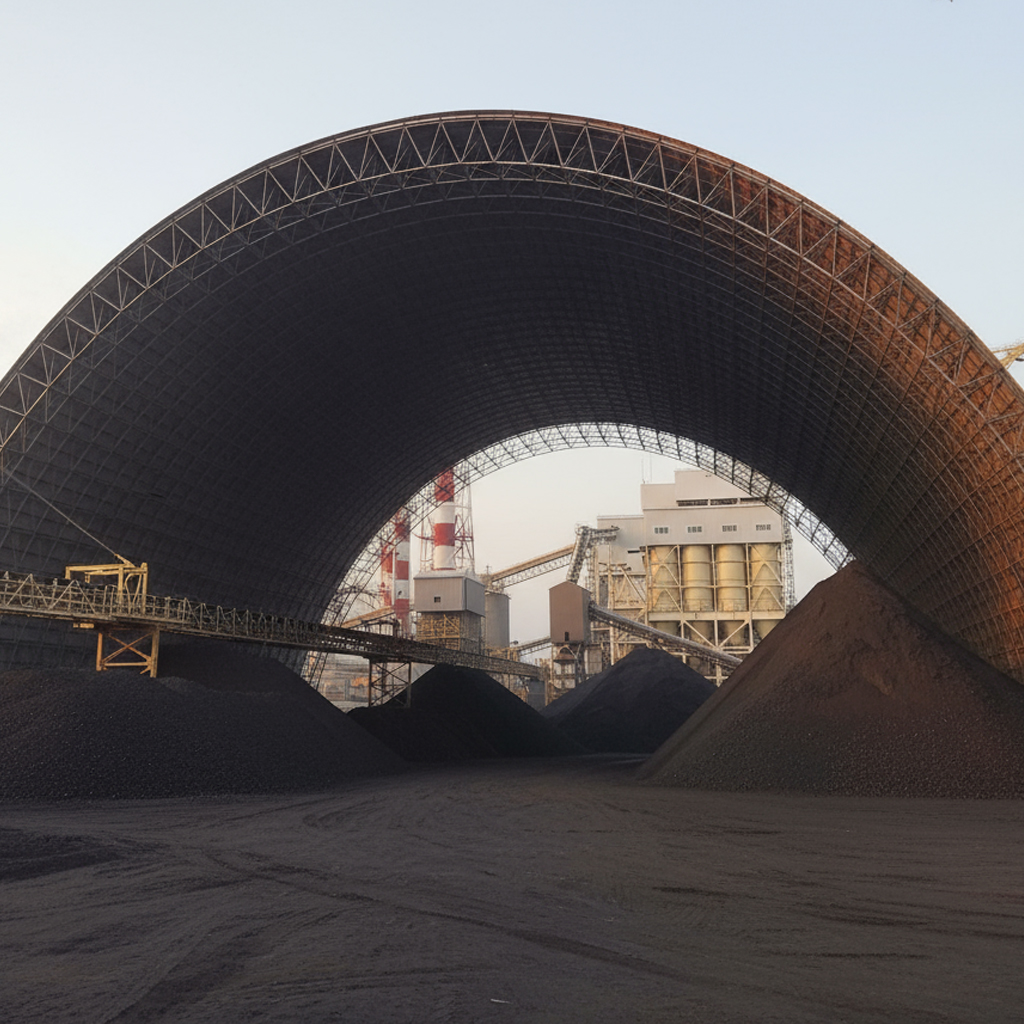

Types of Bulk Cement Storage Solutions

Silo Storage

- Vertical Silos: Vertical silos are the most common storage units, offering high storage capacity while occupying minimal ground space. These are ideal for large-scale operations.

- Horizontal Silos: Horizontal silos are portable and easier to install, making them suitable for temporary sites or smaller-scale projects.

Warehouse Storage

- Bulk Bags & Pallets: For smaller quantities, warehouses utilize bulk bags or pallets, which are easy to handle and store but require more space compared to silos.

Mobile Cement Storage Units

- Advantages of Portability: Mobile units allow for flexibility, especially in remote locations or temporary project sites. These units are compact, easily transportable, and quick to set up.

Key Components of Bulk Cement Storage Systems

Structural Features

- Material Durability: High-quality materials, such as reinforced steel or treated concrete, ensure the storage system can withstand environmental factors.

- Loading & Unloading Systems: Efficient systems, such as pneumatic conveyors or gravity-fed outlets, facilitate smooth operations.

Ventilation & Moisture Control

Proper ventilation systems and moisture barriers are critical to prevent cement clumping and degradation.

Best Practices for Bulk Cement Storage

Site Selection & Preparation

- Proximity to Usage Areas: Selecting a site near the construction or manufacturing area reduces transportation costs and time.

- Ground Stability: A stable, level ground ensures the safety and longevity of storage systems.

Regular Maintenance & Monitoring

- Inspection Protocols: Routine inspections help identify and address potential issues such as corrosion or structural weaknesses.

- Ensuring Structural Integrity: Timely repairs and upgrades are essential to maintain operational efficiency.

Challenges in Bulk Cement Storage

- Moisture Infiltration Risks: Moisture is the primary enemy of stored cement. Preventative measures like sealing and dehumidification are crucial.

- Handling & Transportation Concerns: Improper handling during transportation can lead to material loss or quality compromise.

Innovations in Bulk Cement Storage

- Automation & Smart Systems: Modern storage solutions include automated loading/unloading systems and real-time monitoring for enhanced efficiency.

- Sustainable Storage Solutions: Eco-friendly designs and materials are gaining traction, offering sustainable alternatives without compromising performance.

Conclusion

Bulk cement storage is a cornerstone of modern construction practices, ensuring efficiency, cost-effectiveness, and environmental sustainability. By understanding the various storage options, best practices, and emerging innovations, industries can optimize their operations and contribute to a sustainable future.