Iron ore storage plays a vital role in the global supply chain, ensuring that this crucial raw material remains safe, durable, and ready for industrial use. Iron ore powers industries such as steelmaking, construction, energy, and infrastructure development. Therefore, efficient storage solutions are essential for long-term reliability and sustainability.

This article explores modern iron ore storage solutions, highlighting the best practices, technologies, and innovative methods used globally. Moreover, it provides insights into how industries can overcome challenges while ensuring operational efficiency.

Why Iron Ore Storage is Important

- Maintaining Quality

Iron ore is prone to moisture absorption, oxidation, and contamination when exposed to harsh environments. As a result, proper storage methods are critical to preserve its chemical composition and physical properties. - Environmental Safety

Large-scale ore handling can generate dust, runoff, and environmental hazards. However, advanced storage systems help in controlling emissions and minimizing ecological impact. - Operational Efficiency

Organized storage ensures smooth material handling. In addition, it reduces loading and unloading time while improving supply chain operations. - Cost Management

By preventing spoilage and material loss, companies can save millions of dollars annually. Consequently, efficient storage translates into significant financial benefits.

Types of Iron Ore Storage Facilities

The method of storing iron ore depends on scale, climate, and usage. For example, some industries prefer open stockpiles, while others invest in advanced domes.

1. Open Stockpiles

- Traditionally, iron ore is stored in large open yards.

- Advantages: cost-effective and easy to maintain.

- Challenges: exposure to weather, moisture absorption, and dust emissions.

- Therefore, companies often install dust suppression systems and water sprinklers to improve safety.

2. Covered Sheds

- Large steel sheds protect ore from rain and sunlight.

- Benefits: reduced moisture content and extended shelf life.

- Moreover, they are highly effective in regions with extreme climates.

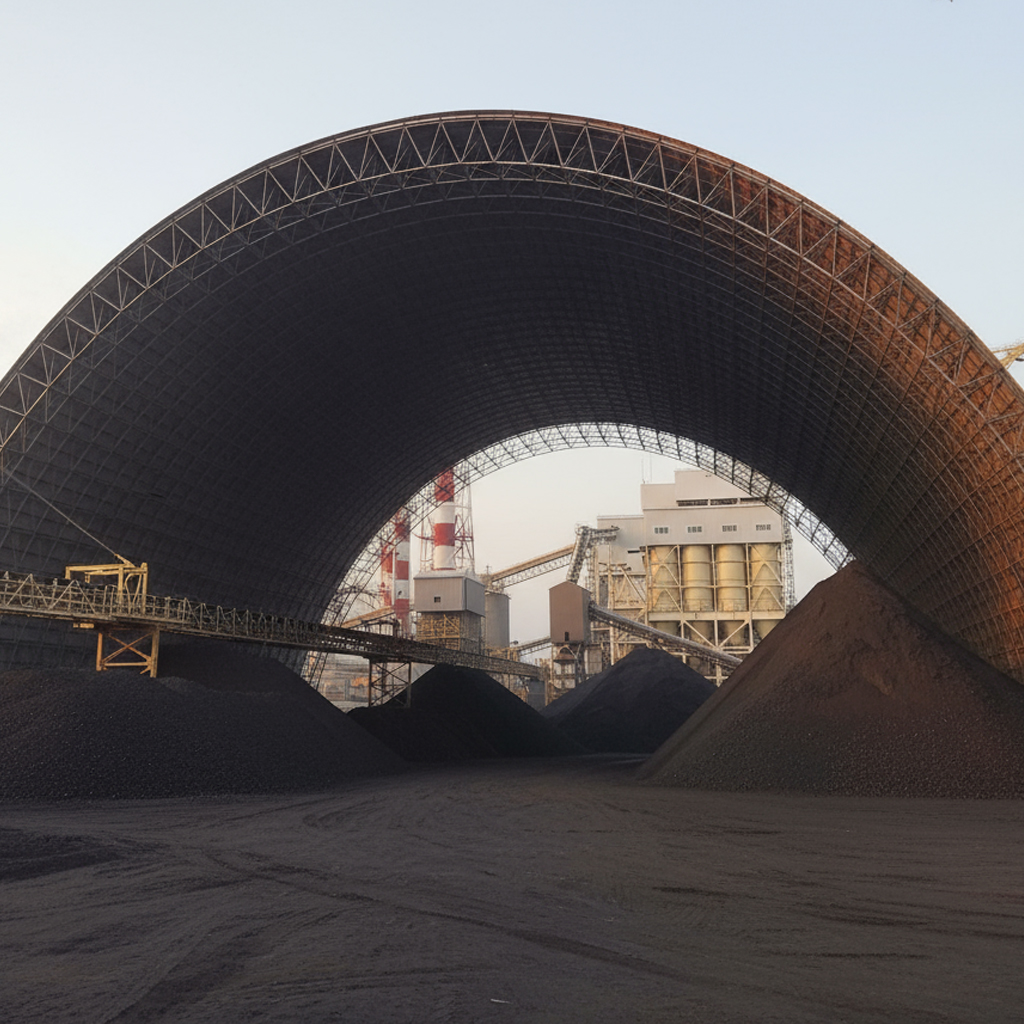

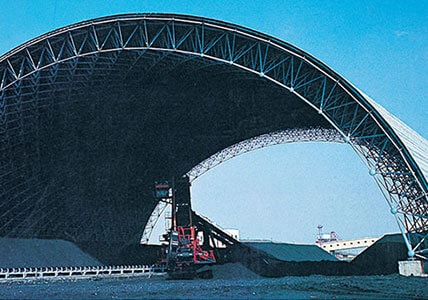

3. Bulk Storage Domes

- Dome-shaped structures provide complete protection from weather.

- Known for durability, strength, and efficiency.

- In addition, they maximize space utilization for bulk materials.

4. Bunkers & Silos

- Useful when ores must be stored near processing plants.

- Equipped with conveyor systems for discharge.

- On the other hand, silos are more suited for smaller, high-density storage needs.

5. Automated Warehousing

- Advanced facilities integrate conveyors, stackers, and monitoring systems.

- Consequently, they enable real-time data tracking and efficient material flow.

Key Considerations for Safe Iron Ore Storage

When planning an iron ore storage facility, several factors matter. For instance, moisture control, structural design, and environmental protection must be carefully addressed.

- Moisture Control

- Excessive moisture can affect ore quality.

- Therefore, solutions such as dewatering systems and waterproof coverings are widely used.

- Structural Design

- Strong frameworks and corrosion-resistant materials ensure durability.

- Moreover, space frames and domes require less maintenance compared to traditional sheds.

- Material Handling Systems

- Stacker-reclaimers and conveyors streamline operations.

- As a result, they improve safety and reduce manpower needs.

- Environmental Protection

- Dust suppression and filtration systems are essential.

- In addition, eco-friendly roofing helps meet sustainability goals.

- Safety Measures

- Fire-resistant materials and safe access routes protect workers.

- Therefore, industries must prioritize compliance with global safety standards.

Modern Technologies in Iron Ore Storage

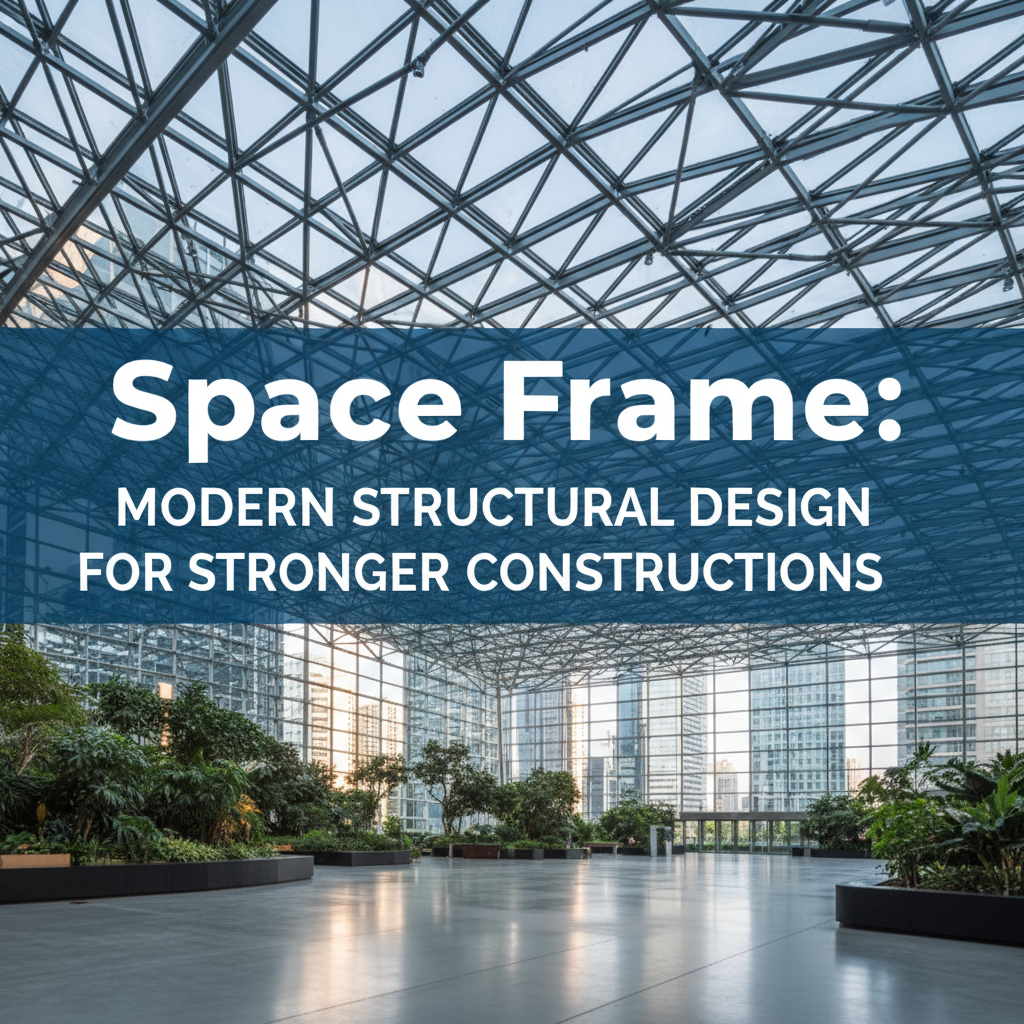

1. Space Frame Structures

Modular and strong, space frames are ideal for large-scale storage. Moreover, their quick installation reduces downtime.

2. Automated Monitoring Systems

IoT sensors track moisture, quality, and inventory. Consequently, companies can make proactive decisions and reduce material loss.

3. Dust & Emission Control Systems

Advanced suppression systems cut emissions. In addition, they ensure compliance with global regulations.

Benefits of Investing in Advanced Iron Ore Storage

- Enhanced Durability – Protects ore from contamination.

- Operational Efficiency – Faster handling with minimal losses.

- Environmental Compliance – Meets sustainability standards.

- Cost Savings – Reduces spoilage and boosts productivity.

- Scalability – Moreover, modern solutions can be expanded easily to meet rising demand.

Challenges in Iron Ore Storage and How to Overcome Them

- Moisture & Oxidation

- Solution: covered domes, dehumidifiers, and membranes.

- Therefore, long-term quality is preserved.

- Space Limitations

- Solution: vertical silos and optimized layouts.

- For example, industries with limited land often rely on silos.

- High Initial Investment

- Solution: modular structures with phased installation.

- As a result, ROI improves over time.

- Environmental Regulations

- Solution: eco-friendly materials and emission controls.

- Moreover, compliance ensures better brand reputation.

Future Trends in Iron Ore Storage

- Sustainable Materials – Eco-friendly, corrosion-resistant steel.

- Automation & Robotics – AI-driven handling and drone monitoring.

- Hybrid Energy Facilities – Solar-powered storage domes.

- Digital Twin Technology – Therefore, predictive maintenance becomes easier with real-time simulations.

Iron ore storage is not just about stacking raw material; it’s about ensuring safety, efficiency, and long-term value. Moreover, adopting modern solutions such as domes, silos, and automated systems safeguards industries against losses and enhances sustainability.

As global demand continues to grow, innovative and eco-friendly storage systems will play a key role in shaping future industrial infrastructure.

Hindustan Alcox Ltd, a pioneer in advanced steel structures, space frames, and bulk storage solutions, continues to deliver reliable facilities tailored to complex industrial needs. Therefore, with a focus on durability and engineering excellence, the company ensures long-term success for its clients.