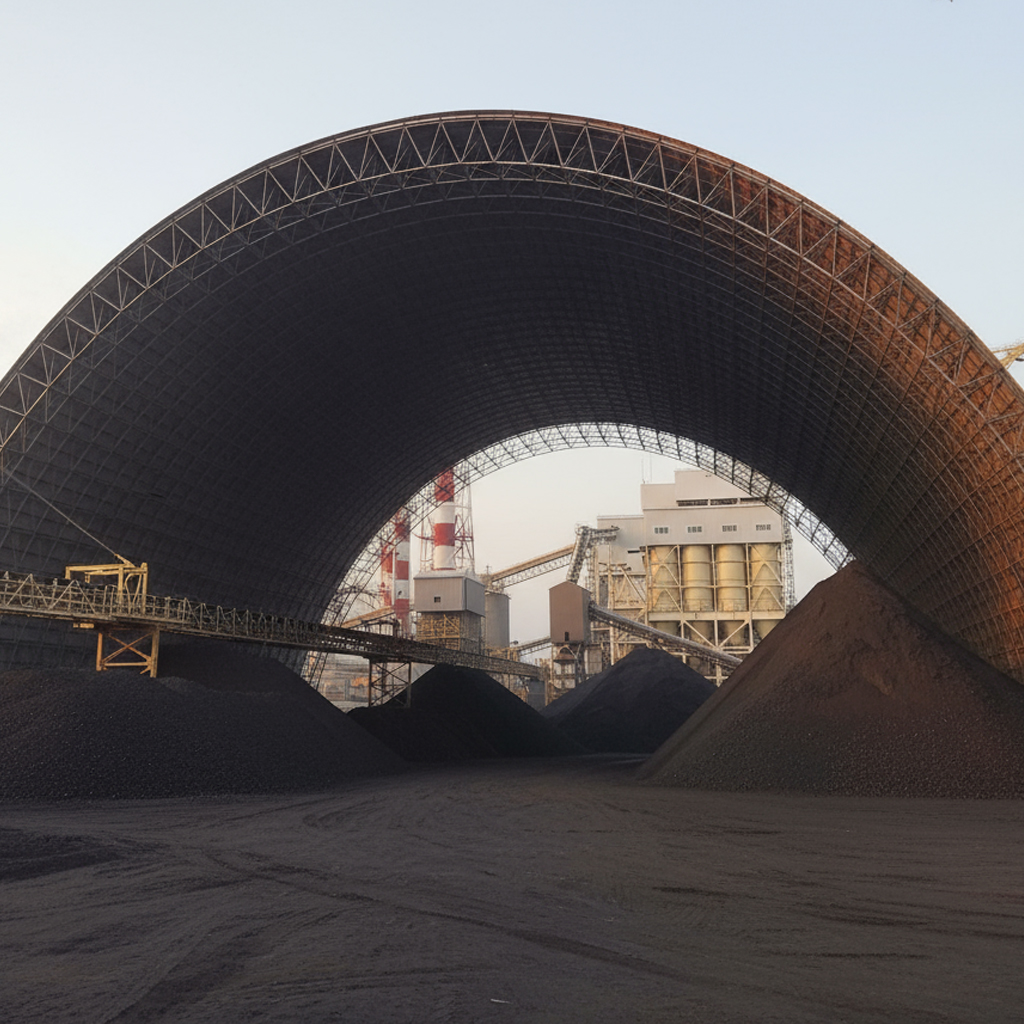

Coal Storage is the primary fuel being used for power generation in thermal power plants. Most of the power generation in India is generated by coal based power plants where coal is received from coal blocks/Mines by means of transportation (by belt conveyors, by rail or by ship depending upon the distance and availability of transport). Then the Coal is dropped in a coal yard and stored in stockpiles.

As far as optimum power generation is concerned, a healthy emphasis needs to be given for its bulk storage and proper handling. Preparation of coal before feeding it into the boiler plays crucial role for achieving better combustion. Irregular and big-sized lumps of coal may cause the following problems:

- Improper combustion & inadequacy in furnace temperature.

- Increment in unburnts of the ash.

- Reduction in thermal efficiency.

Once Coal is reduced in size by crushing and pulverizing, crushed coal not only ensure efficient combustion but also become an economical asset for power generation in thermal power plant.

Coal Storage Types

Coal storage can be done in two ways:

- Open coal storage

- Covered coal storage

Most of the coal stockpiles in the power plant are open type. But with the passage of time, various problems are experienced with open stockpile system and potential need for covered coal storage system is felt. The salient features and benefits of the covered coal storage as compared to open coal storage are as follows:

- Reduction in spontaneous combustion of coal, by virtue of no exposure to sun.

- Minimum dust emission in the stockpile.

- No air pollution.

- Elimination of rainfall and moisture problem :

- Prevention of Loss of Gross Calorific Value (GCV) of coal

Stocking of coal in covered coal storage system not only minimizes the above various problems that had occurred in stocking of coal in open coal storage system, but also improves combustion, boiler efficiency and overall power generation in thermal power plant.

Factors to Maximize Output Power Generation

In coal/lignite storage systems, the implementation of a various factors needs to be performed to maximize power generation in a way, which is consistent and flexible enough to suit the requirements without extensive modifications.

These major factors are as follows:

- ‘Fuel Quality’: Fuel quality of coal which is generally quoted in terms of its gross calorific value (GCV) along with its moisture and ash content impacts on whole plant operational efficiency. Assessing fuel quality and choosing fuel of maximum gross calorific value and less moisture & ash content improves combustion and power generation as well.

- ‘Reheat Stages’: Earlier heat cycles were not used in power plants, but with time, the potential benefits of reheat cycles are considered and come as one of the correction factor in improving overall plant efficiency.

- ‘Maintenance of Ambient Temperature’: Ambient temperature is the temperature in the surrounding of boiler during plant operation. Change in the ambient temperature tends to affect performance and load capability of gas turbines, cooling system performance . Hence it is better to keep the ambient temperature maintained during plant operation for maximum power output.

- ‘Fuel Sulphur Content’: Sulphur content in fuel have adverse effect on plant efficiency. ‘Formation of corrosive acids’ and ‘boiler sensible heat loss’ can be avoided by properly supervising and eliminating the sulphur content in coal.

- ‘Excess Air & Unburned Carbon in Ash’: One of the major operation issues in power plant is presence of excess air and unburned carbon content is ash which may directly affect boiler thermal losses and can be suppressed by site level operations.

Safety Measures to Avoids Hazards in Coal Storage

These safety measures are steps taken to increase or ensure safety or protection from perils of coal storage and handling. In the publications of National Fire Protection Association (NFPA), they identifiy the threats associated with coal storage, and its handling & gives recommendations for protection against these threats. In addition to those safety preventions, some addition safety measures are as follows:

- The coal stockpiles should be kept away from moisture.

- Coal storage or lignite Storage piles should be emphasized to prevent those pockets of coal, which are potential source of spontaneous combustion. Coal storage should be done for as short a duration as possible. In order to reduce air within the stockpile, Coal should be piled in layers.

- Coal stockpiles should be monitored constantly for hot spots using temperature detection systems. These sensors are designed to avoid harsh conditions in coal handling and processing.

- A management strategy should be followed to replace the ignited coal on its occurrence. In addition to this, the access should be provided for firefighting.

- There should be no scope for dust to accumulate inside the coal storage shed. Otherwise, dust removal systems should be provided for all surfaces where dust may accumulate.

- An absolute minimum distance should be maintained between Ignition sources and coal stockpile. Every electrical equipment should be properly grounded, to minimize the effect of static electricity hazards. All machinery and electrical equipment inside coal storage shed should be checked properly for use in hazardous locations.

- There should be automation in turning all electrical circuits on/off without the need for personnel to enter dust-emitting locations.

- In order to reduce the chance of methane (and, in case of fire, smoke) to occur around coal storage, a sufficient ventilation system should be provided. At the apex, adequate ventilation should be provided to take advantage of the chimney effect.