Introduction to Coal Gasification

Coal gasification is an innovative process designed to convert coal into a versatile fuel source. With rising energy demands and environmental concerns, coal gasification has gained attention for its potential to make coal—a traditionally polluting energy source—cleaner and more efficient.

What is Coal Gasification?

- Definition & Overview: Coal gasification is a thermochemical process that transforms coal into a gaseous mixture primarily made up of carbon monoxide (CO), hydrogen (H₂), carbon dioxide (CO₂), and methane (CH₄). This gas mixture, known as synthesis gas or syngas, can be used as fuel or as a raw material for chemical production.

- Historical Background of Coal Gasification: The concept of gasifying coal dates back to the early 19th century, where it was initially used to produce “town gas” for street lighting and heating. Advances in technology have expanded its application in various industries, especially in power generation and chemical manufacturing.

Science behind Coal Gasification

Key Reactions Involved in Gasification

At its core, coal gasification involves a series of chemical reactions, primarily:

- Combustion Reaction: Coal reacts with oxygen, producing carbon dioxide and heat.

- Steam Gasification Reaction: Coal reacts with water vapour to produce hydrogen and carbon monoxide.

- Water-Gas Shift Reaction: Carbon monoxide reacts with water vapour to produce carbon dioxide and more hydrogen.

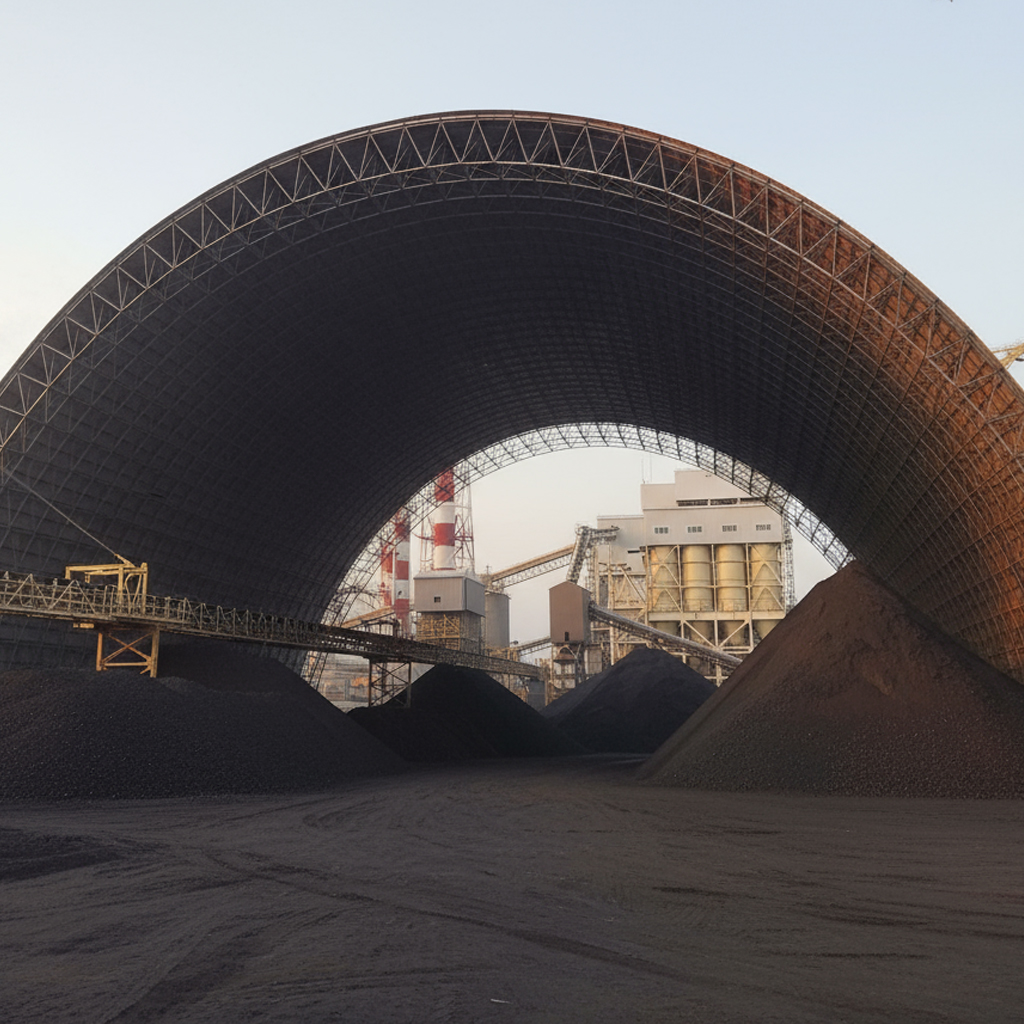

Major Components in the Gasification Process

The coal gasification process typically includes a gasifier unit, where coal is mixed with a controlled amount of oxygen and steam. This mix undergoes partial oxidation at high temperatures, creating syngas.

Types of Coal Gasification Processes

- Fixed-Bed Gasification: In fixed-bed gasification, coal is introduced in a stationary bed, where gas flows upward, creating a simple but low-efficiency process.

- Fluidized-Bed Gasification: Here, coal particles are suspended in the gas stream, promoting a thorough mixing of coal, steam, and oxygen, which enhances efficiency.

- Entrained-Flow Gasification: Entrained-flow gasification processes coal at higher pressures and temperatures, ensuring complete coal conversion and high syngas purity.

Benefits of Coal Gasification

- Environmental Advantages: Unlike direct coal burning, gasification allows for better control of emissions, reducing pollutants like sulfur dioxide (SO₂) and nitrogen oxides (NOₓ). Carbon capture and storage (CCS) can be integrated with gasification to significantly lower greenhouse gas emissions.

- Energy Efficiency & Conservation: Coal gasification is more efficient than traditional coal combustion. The heat generated can be used in combined-cycle plants to generate electricity, maximizing energy output.

- Coal Gasification vs. Direct Combustion: In direct combustion, coal burns completely, releasing carbon and other pollutants directly. Gasification, by contrast, is a cleaner process that reduces harmful emissions and can be optimized for higher efficiency.

Uses of Coal Gasification Products

- Synthetic Natural Gas (SNG): One of the primary outputs of coal gasification is SNG, which can replace natural gas in heating and power generation.

- Hydrogen Production: Hydrogen produced from coal gasification is a valuable fuel source for various industrial applications, particularly in fuel cells for clean energy.

- Power Generation & Chemicals: Syngas from coal gasification can be used to generate electricity in integrated gasification combined cycle (IGCC) plants or to produce chemical feedstocks like methanol and ammonia.

Key Challenges in Coal Gasification

- Technical Challenges: High operating temperatures and pressures present technical hurdles in maintaining stable gasification, equipment durability, and efficient reaction management.

- Environmental Concerns: Despite emission reductions, coal gasification still produces CO₂ and other by-products, which need to be managed to minimize environmental impact.

- Economic Feasibility: While gasification has environmental advantages, the initial setup and operational costs are substantial. Government incentives and advances in technology are crucial for improving economic feasibility.

Coal Gasification in Industry Today

- Prominent Industrial Applications: Many industries use coal gasification for large-scale power generation and chemical production. Companies worldwide invest in gasification technology to enhance sustainability.

- Current Trends in Coal Gasification Technology: Technological advances focus on integrating renewable energy with gasification and improving efficiency. Innovations like plasma gasification and hybrid systems are pushing the boundaries of traditional coal gasification.

The Future of Coal Gasification

- Innovations & Advancements: Research is underway to develop cleaner, more efficient methods of coal gasification. Advances in carbon capture and gasification technology are reducing emissions and improving energy yields.

- Potential for Green Energy Integration: Integrating coal gasification with renewable energy sources and hydrogen production holds promise for reducing fossil fuel dependence.

Coal gasification offers a way to use coal more cleanly and efficiently. While challenges remain, advances in technology are continually improving its environmental and economic viability. As industries and governments invest in sustainable energy, coal gasification may play a vital role in meeting energy demands while reducing emissions.