Clinker Storage – Economical Ways to Store Clinker

Hindustan Alcox Ltd is an India based limited company dedicated to design, fabrication and erection of Clinker Storage Shed. This paper presents one of the most common applications of space frame shed and Clinker storage significance

Clinker:

Clinker consists of various calcium silicates including alite and belite. Tricalcium aluminate and calcium aluminoferrite are other common components. These components are often generated in situ by heating various clays and limestone.

Clinker consists essentially of four minerals:

- Alite: approximately tricalcium silicate (typically about 65% of the total)

- Belite: approximately dicalcium silicate (typically about 15% of the total)

- Tricalcium Aluminate: Typically about 7% of the total

- Tetracalcium Aluminoferrite: Typically about 8% of the total

Clinker is the main ingredient of Cement. Portland cement is obtained by grinding Clinker with only addition of minor amounts of a few other minerals, so its composition does not depart far from that of Clinker. Other Cements (i.e. non-Cements, for example pozzolanic Cements, blast furnace slag Cements, limestone Cements and masonry Cements) contain larger amounts of other minerals and have a much wider composition range.

Although the other potential ingredients may be cheap natural materials, Clinker is made in an energy-intensive chemical process. Nearly, two billion tons a year of Clinker is made world-wide, and the details of its formation are therefore of great economic significance, since no viable alternative ingredients for making Cement-like materials currently exist.

Clinker is a complex mixture of different minerals, and so its production depends on a multi-dimensional control of raw materials and a multi-staged heat treatment

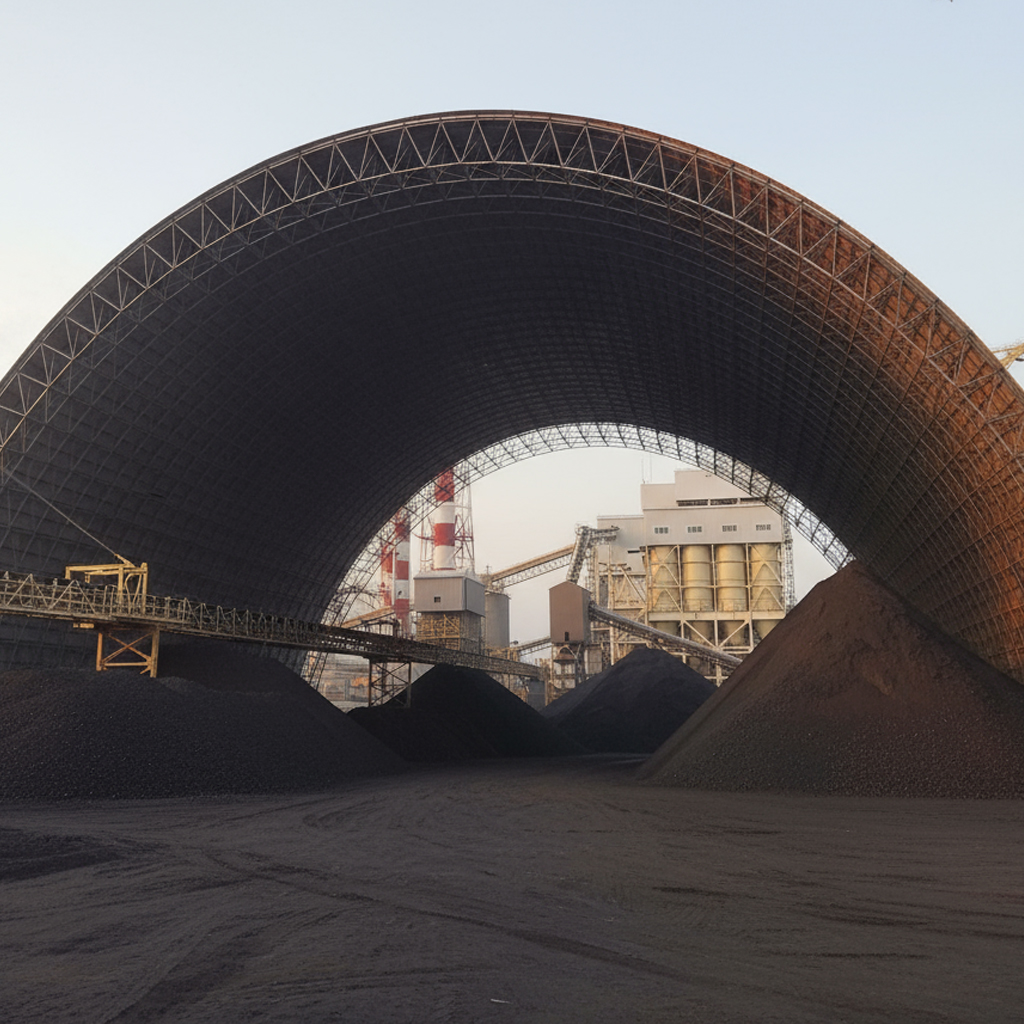

Storage of clinker

Cement is caustic, so it can cause chemical burns. The powder can cause irritation or, with severe exposure, lung cancer and can contain some hazardous components such as crystalline silica and hexavalent chromium . Environmental concerns are the high energy consumption required to mine, manufacture, and transport the cement and the related air pollution, including the release of greenhouse gases (e.g., carbon dioxide), dioxin, NOx , SO2 , and particulates. Therefore, it is essential that clinker should be properly stored in covered sheds.

The construction systems uses mild steel in case of clinker storage, no welding is required because the connection of the member consists of a very efficient moment-resistant mechanical joint. Clinker storage shed may be built in single- or double-layer configurations, depending on the load and span. Experience suggests large spans are required in clinker storage a-double-layer is the most cost-effective

Clinker storage sheds are often built over operating stockpiles since construction can proceed without interrupting operations. Because our erection process does not require machines to be installed internal periphery of the span.

Roofing of the structure:

Galvalume is typically use for roofing purpose, Galvalume is lustrous spangled appearance is attractive enough to be used without painting. The GALVALUME sheet is a unique product which is suitable for heating and ventilation applications. It has better resistance towards oxidation and can withstand temperatures up to 315°C without discoloration. This feature of Galvalume enables us to use on limestone shed for roofing purpose.

Key Features

- Smooth Surface and uniform spangled appearance

- Excellent quoting with anti-fingerprint to ensure better appearance and longer life

- Surface treatment as per ROHS (Restriction On Hazardous Substance) norms

- Wider thickness range with tighter tolerances to ensure precision in end-applications

Advantage of Clinker Storage Shed:

- For achieving effective prevention and control of potential fugitive emission

- Lesser Operation and Maintenance cost

- Comply with current environmental guidelines by CPCB (Central Pollution control board)

- Protection from weird environmental condition

Conclusion:

Our Structure is fully Complying with new environmental regulations for air quality, Prevention and control of fugitive emission. Instead of investing in temporary solution, it is recommended to adopt permanent solution. Our solutions presented here not only allow affordable compliance, but also enhance the reputation of your plant. In addition, one-time investment is much more economical than the periodic investments