In cement plant, one of the major component for clinker or cement formation is limestone. Dispatch, storage and processing of limestone can be divided into five main operations: i.e. crushing/grinding, sizing, benefication, storage/loading-out & transport. For cement production, limestone is first reduced in size by processing through a series of crushers and grinders and then limestone storage is done under covered sheds to get rid of cement industry impacts such as environmental Issues, health & safety issues and many more.

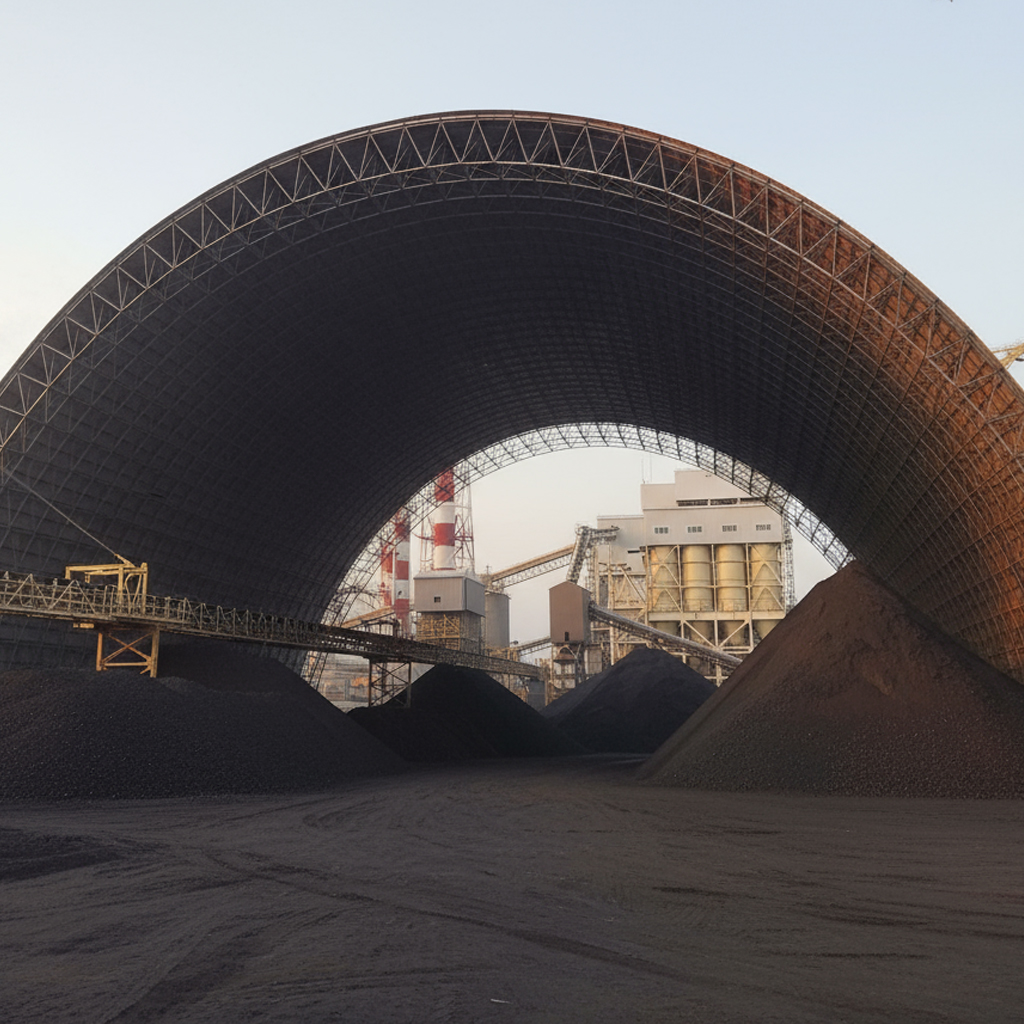

Clinker Storage:

After limestone is reduced in size by processing, the stored limestone is then mixed with some mineral aggregates (siliceous, aluminous, and ferrous materials) and water in high temperature to form clinker. After cooling, clinker storage is done under covered sheds or clinker dome. The nodules of cement clinker are then ground to the consistency of face powder to produce powdered cement.

Cement Industry Impacts & Management for Limestone & Clinker Storage:

The cement manufacturing industry exhibits various issues associated with cement and lime manufacturing, which occur during the operational phase. Emissions associated with intermediate and final materials handling and storage are responsible for the followings industrial Impacts :

- Environmental issues

- Air Emissions

- Energy consumption and fuels

- Waste water

- Solid waste generation

- Noise

- Labor Health & Safety

- Safety from Dust

- Safety from Heat

- Safety from Noise & vibrations

- Physical Hazards

- Safety from Radiation

- Environmental Health & Safety

Hindustan Alcox Limited specializes in providing storage solution for limestone with long span steel structure to get rid of above-mentioned cement industry impacts. Limestone storage shed, engineered by the Hindustan Alcox Limited is the best available choice to cover limestone stockpiles for the most challenging environment. Clinker storage sheds or Limestone storage sheds are often built over operating stockpiles so that construction may proceed efficiently without interrupting operational work.