Coal storage sheds are integral components of modern bulk material handling infrastructure, designed with strong materials to safeguard stored coal from rainwater infiltration, moisture damage, and surface runoff that could compromise its calorific value and operational quality.

The design of these structures also incorporates techniques to prevent coal self-combustion and limit material loss during storage and handling.

Coal Sheds: Large-Scale Fabricated Structures for Efficient Storage

Coal storage sheds are large-scale fabrication projects constructed using steel and reinforced concrete, designed to withstand harsh industrial environments.

Not only do these structures protect from weather elements, but they also maintain consistent coal quality over extended storage durations while offering weather protection as well.

Key Design Considerations:

- Protective structures against rain, stormwater, and humidity to minimise lump formation and calorific value loss.

- Implementation of temperature control and ventilation mechanisms to avoid spontaneous combustion in stockpiles.

These sheds are used in power plants, fabrication units, and mining facilities to ensure a continuous fuel supply with minimal deterioration.

Historical Significance and Engineering Development

Early coal sheds were simple structures; over time, they have progressed into complex engineered buildings capable of holding vast amounts of coal safely.

At Bar U Ranch National Historic Site in Canada, for example, the Coal Shed represents early 20th-century craftsmanship in industrial architecture by combining functionality and structural integrity using timber framing and efficient ventilation systems.

This evolution illustrates how engineering design and fabrication expertise have contributed to shaping modern methods for coal protection and bulk storage.

Coal Storage in Thermal Power Plants

Thermal power generation requires efficient coal handling systems and enclosed storage sheds that safeguard the environment while minimising fuel losses.

Modern sheds ensure the coal stays dry, usable, and reduces waste due to exposure or combustion risks.

Significant Challenges During Coal Storage Include:

- Rain and runoff protection: Prevents leaching and degradation of coal quality.

- Spontaneous combustion control: Managed through temperature regulation and air circulation.

Expert fabrication contractors specialising in heavy-duty industrial storage construction design, construct, and install these advanced systems.

Preventing Spontaneous Combustion and Moisture Damage

Coal has the tendency to oxidise, leading to self-heating and combustion under certain circumstances.

Advanced coal storage sheds help avoid this by controlling temperature buildup and ensuring uniform ventilation.

Advantages of Space Frame Fabrication Structures:

- Protection from rainwater infiltration, maintaining coal’s heating efficiency.

- Reducing lump formation to ensure smoother flow during reclaiming and feeding operations.

Modern Enclosed Coal Storage Sheds: Long-Term Protection for Coal and Pet-Coke

Enclosed coal storage sheds offer long-term solutions for protecting coal and pet-coke against rain and wind exposure, keeping their calorific value intact and avoiding surface runoff contamination.

These systems, designed for thermal power plants, cement industries, and metallurgical applications, provide reliable fuel quality while lowering operating costs and material losses.

Conveyors and Reclaimers for Controlled Material Flow

Efficient material movement is essential in large-scale coal storage and fabrication projects.

The integration of conveyors, stackers, and reclaimers into engineered coal handling systems offers multiple benefits, including:

- Preventing material blockage and coal lump accumulation.

- Enhancing moisture control through covered feeding and transfer zones.

By integrating advanced material handling systems with enclosed storage, industries achieve both improved productivity and reduced maintenance requirements.

Optimised Reclaim Systems for Uniform Coal Distribution

An optimised coal reclaim system helps maintain consistent quality while avoiding segregation within stockpiles.

Common approaches include:

- Parallel tunnel reclaim systems with integrated conveyors to facilitate material blending.

- Arc-arranged sequence reclaim designs providing high reclaim capacity and maintaining uniform temperature distribution to prevent combustion risks.

These engineered solutions form part of advanced heavy fabrication systems for long-term, high-volume industrial operations.

Coal Filters and Cleaning Systems

While coal storage sheds primarily provide protection, integrating cleaning and filtration systems enhances operational efficiency by eliminating impurities introduced during runoff or handling.

These systems help:

- Reduce emissions during combustion or processing.

- Guarantee high-quality output through refined coal preparation.

Fabricated modular designs make it easy to integrate these systems, offering adaptability for different coal grades and storage capacities.

Open vs. Closed Coal Storage

Open coal stockpiles are prone to environmental harm such as runoff, rainwater contamination, and spontaneous combustion, while closed sheds offer:

- Controlled environments to avoid coal wetting and degradation.

- Increased safety and material preservation.

By protecting material from direct exposure to the elements, closed sheds ensure optimal storage efficiency with minimal operational downtime.

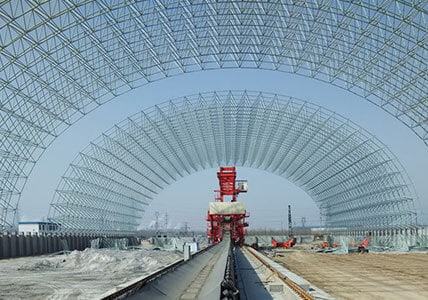

Dome-Shaped Coal Storage Sheds

Dome-shaped coal storage sheds are increasingly popular in industrial and power plant projects due to their aerodynamic design, low maintenance, and high strength-to-weight ratio.

Advantages of Dome Sheds:

- Protect coal from rainwater infiltration while offering extensive overhead protection.

- Minimise lump formation and combustion risks by maintaining stable internal conditions.

- Integrate seamlessly with stacker-reclaimers, conveyors, and feeding systems for efficient operations.

Dome sheds offer the most cost-effective and sustainable method of coal storage for modern industries.