The petroleum coke, also known as petcoke, is essentially a solid carbonaceous material formed during the operations of coker units in oil refineries and other units for cracking processes. Petcoke is mainly composed of carbon and heavy hydrocarbons. The consumption of this fossil fuel has increased fast during the last few years due to the high calorific value and low ash content of this fuel that make it an efficient source of power. The coal can basically be found in the construction (cement) industry, power generation, and the production of aluminum. On the other hand, wrong disposal may result in a health and safety risk, environmental pollution, as well as build up of landfills.

In this blog, we are going to focus on the benefit of proper storage of petcoke and how it can help industries become more green and environmentally conscious.

Importance of Proper Storage for Petcoke

Efficient storage remains the best way to protect the life quality of petroleum coke and prevent environmental dumping. Petcoke often produces dust and fine particles that are carcinogenic and may harm the community’s health if not stored correctly. Additionally, petcoke contamination in the groundwater sources poses a danger to ecosystems and public health.

Advantages of Petcoke Storage

- Environmental Benefits

Reduction in Air Pollution

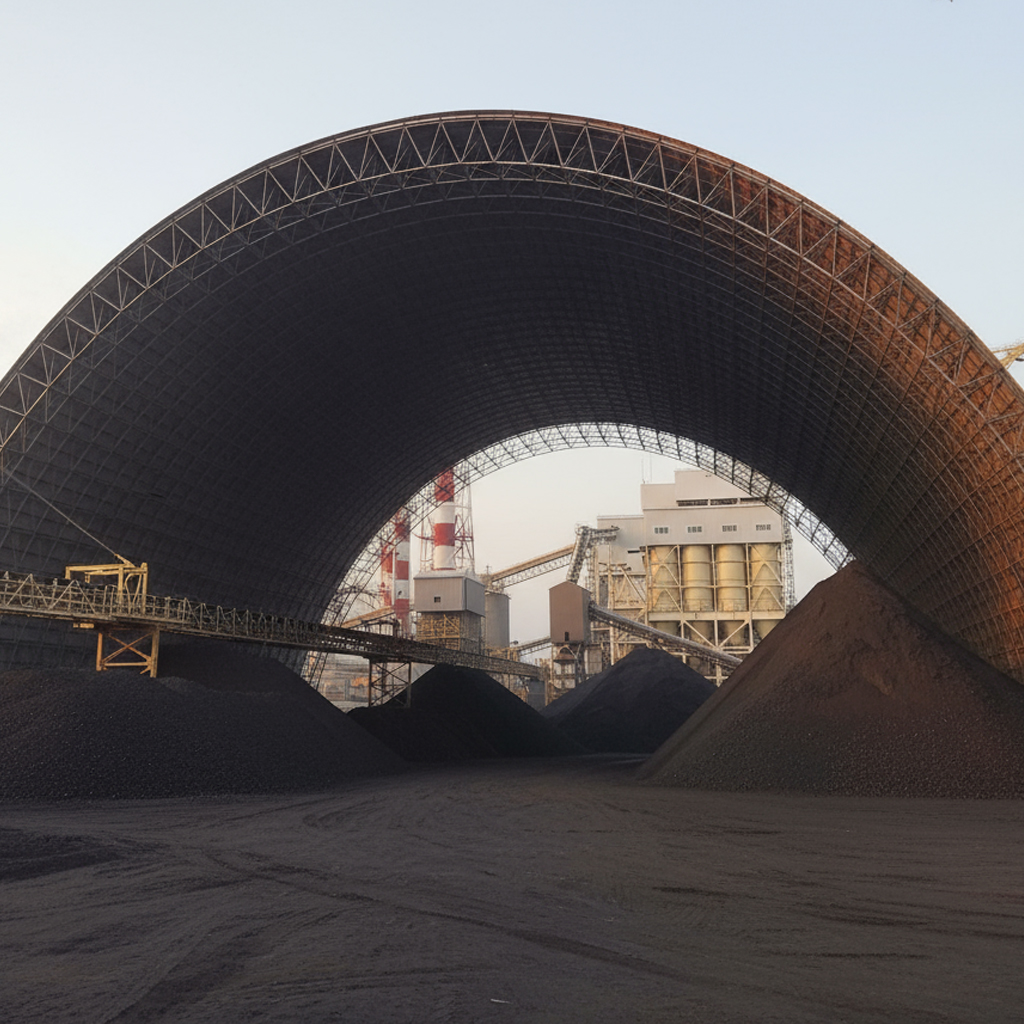

Petcoke storage techniques using structures such as container yards and domes allow for capturing fugitive dust emissions that would otherwise be released into the atmosphere. These kinds of accommodation generate fewer airborne pollutants and consequently leads to cleaner air quality that is of enormous value for the benefit of both environmental organisms and communities around the place.

Prevention of Groundwater Contamination

Enclosed storage facilities prevent discharge of poisonous compounds in the soil and under-ground purifying systems. These systems cut the risk of contamination by avoiding all proximity to nature which is important to protect the water resources and ecosystems.

- Cost Savings

Lower Risk of Product Loss Due to Improper Storage

The designing of storage systems as such preserves and increases product longevity. This process minimizes the possibility of stockout during unpredictable circumstances like extended closures due to weather conditions. Improved processes decrease spoilage which means extra revenue for the companies which use petcoke as a fuel or as raw material.

Reduced Maintenance Costs for Equipment

In the no-overhead situation the balls need less protection compared to the ones stored in an open-air environment, prolonging the lifetime of equipment and infrastructure. These technologies lower the operations’ costs and increase the reliability of machines by reducing risks from factors that can lead to the machines running improperly.

- Increased Efficiency

Easy accessibility and convenience.

The system of storing petcoke helps even loading, unloading and retrieval of the stock and so it makes the transportation and operation easier to manage. Installing the storage structures also helps in handling and managing the petcoke. It promotes a smooth work process, and allows the performance gain in a short time frame.

Improve organization and inventory management

It is important to have a structured storage system to help keep the inventory systematically organized. It also helps in equitable distribution, thus prevening stock inadequacies or insufficiency. Industry can manage their resources well and can cut up the operational disruptions by implementing proper storage systems.

- Safety Improvements

Onboarding and controlling of petcoke storage systems can help in proper workplace safety. Employee;s exposure to hazardous conditions will be dramatically reduced and thus, the number of incidents involving such exposure will be minimized. Enclosed storage structures reduce the risk of fires, spills, and emissions. It promotes a risk-free workplace for employees and the people in nearby residential areas.

Safety Measures and Environmental Responsibility in Petcoke Storage

One of the most important aspects, apart from the advantages, is the proper supervision of petcoke emissions and the prevention of spontaneous combustion. Properly enclosed or covered petcoke storages reduce the fugitive emissions, whereas the right ventilation systems prevent accumulation of gasses inside the storages that can cause spontaneous combustion. Emergency monitoring of temperatures and humidity levels is critical for detecting combustion-prone spots and taking quick action to limit the probability of fire occurrence.

Also, strong operational procedures and staff training programmes that are comprehensive should be adopted to prevent health hazards that can be prevented by storing petcoke. The proper handling lessons on safety protocols, methods and the ways of transport, storage, and handling help to avoid the higher risk of accidents or damage. Putting resources in devices such as moisture control systems, fire detection systems, and automated monitoring machines will for sure raise the level of the preventive measures against spontaneous combustion.

Trust Alcox to Help you Setup a Petcoke Storage

The key area of expertise for Hindustan Alcox Limited lies in conceiving best designed and built storage systems that do not fail to meet the particular needs of petcoke storage. We have a long track record in industrial storage construction. We build storage containers, such as silos and domes, that categorically restrain petcoke emissions and practically exclude environmental contamination.

Partnering with Hindustan Alcox Limited for petcoke storage setup guarantees a proper integration of best practices, cutting-edge technology, and industry expertise that will ultimately promote sustainable petcoke management and foster a safer, more efficient working environment.