Introduction

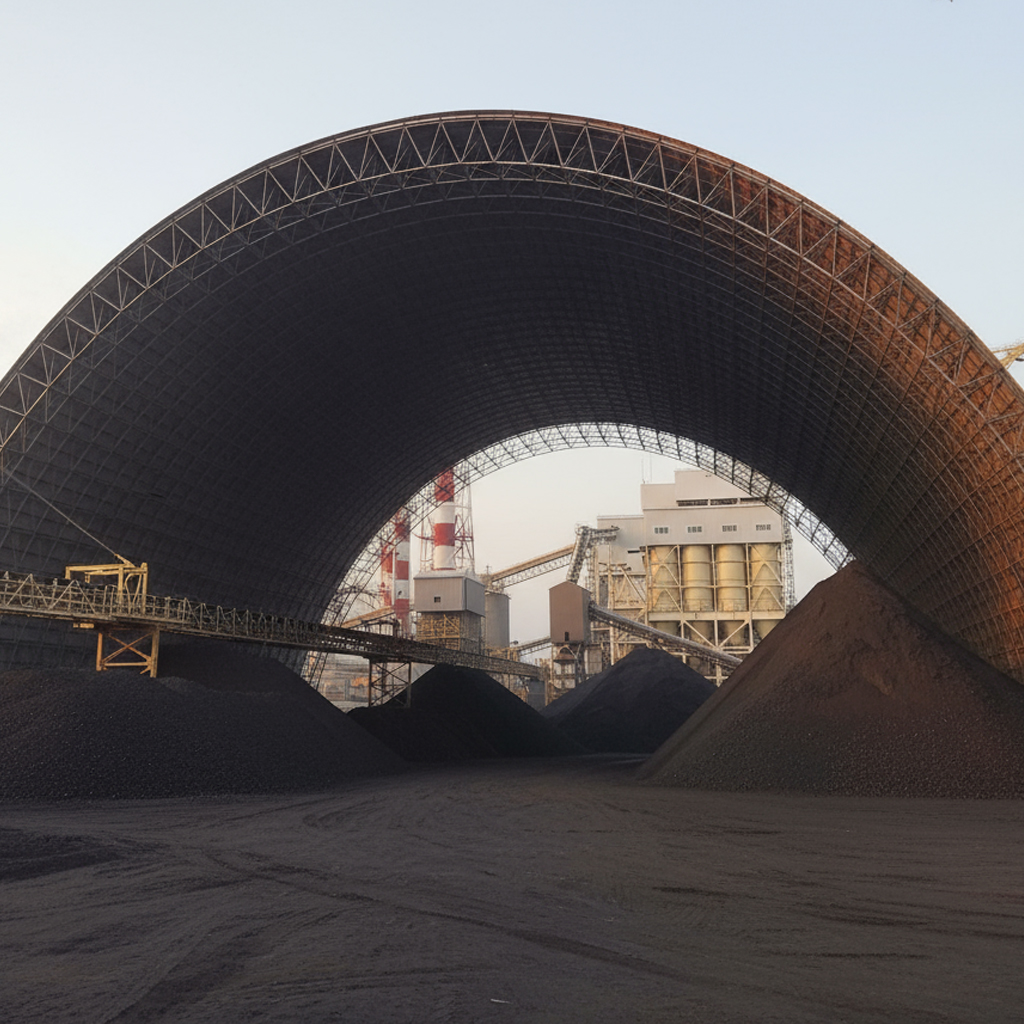

In the Industrial areas, responsible resource management is quite difficult, not only economically but also for environment. Iron ore storage sheds offers several advantages that contributes in cleaner air, reduce pollution, prevents wastage of the iron ore, quality control of iron ores and safety measures. Let’s explore the significant advantages of iron ore storage sheds.

Dust and Air Pollution Mitigation

When iron ore is not kept in proper storage than it can create the dust particles that pollutes the air. By storing iron ore in enclosed facilities like storage sheds than dust emission are significantly reduced. Iron ore storage sheds helps in maintaining air quality, preventing nearby communities from respiratory issues and maintaining the overall environmental balance.

Prevention of Water Contamination

Iron ore, especially in its raw form, can contain various impurities that are harmful for aquatic life and water quality. Improper storage such as leaving iron ore in heaps exposed to rain can lead to wastage of iron ore as well as it can mix with nearby water bodies that results into contaminated water bodies. Proper storage practises can leads to prevent water contamination and wastage of iron ore.

Preserving Quality of Iron Ore

Iron ore is vulnerable to degradation and contamination when exposed to environmental elements. Storage sheds provide the controlled environment to shield the ore from moisture and dust. By maintaining the quality of the ore these sheds ensure that the material retains its original form so that it is suitable for various industrial applications without compromising in quality standards.

Enhanced Safety Measures

Safety is important in industrial operations. Iron ores storage sheds are constructed with strict safety measures in mind. These sheds undergo severe engineering assessments to ensure the safety of the workers of the Industry. By providing a secure environment, these sheds minimize the risk and provide the safe working environment to the employees.

Iron Ore Processing Plant & Mining

How Iron Ore Mining, Used and Processed? Finding a productive location, blasting and drilling the ore, and then moving it to the primary crusher for processing are the usual steps in the mining of iron ore. Large open pits are mined, and the ore is gradually extracted using benches or steps. When upper-level ore is extracted, the benches give access to progressively deeper ore. The ore is blasted and drilled after the surrounding rock and dirt have been removed. Iron ore mining in a large span process plant with modern technology offers the expected results.

Conclusion

Iron ore storage sheds offers a wide range of benefits from preserving quality of iron ore and reducing of environmental impact to ensure operation efficiency and safety. These structures play a vital role in supporting iron and steel industry while simultaneously contributing to environmental protection and sustainable resource management.