A finely grounded inorganic material that may be added to mortar in order to improve or achieve special properties, are Additives. The use of additives to enhance the properties of mortar or renders has taken place for many centuries. In big cement plants, Additive storage in bulk is carried out and added to subject material to improve its inherit properties, performance, efficiency and reduce cost.

The potential hazards due to additive storage concerning efficiency and production in the cement plant, varies according to the nature and the concentration of the different chemical components present, are as follows:

- Moisture problem due to high reactive tendency

- Particle Segregation Problem

- Caking Problem by virtue of crystallization, adsorption

- Chemical oxidation under high temperature

- Flow problem in handling equipments

Preventive Measures to Avoid On-Site Hazards

In order to avoid on-site hazards concerning efficiency and production in the cement plant, the recommended preventive measures are as follows:

- ‘Using moisture barrier process’, ’open space & air circulation’, ‘water leak elimination’ are some of the techniques that can be used in purpose to prevent additive storage not only from moisture problem and particle segregation problem but also from flow problem in handling equipments.

- Caking problem is complete or partial solidification of additives by virtue of crystallization, adsorption after a long storage time. Additive Storage stockpiles should be monitored at regular intervals to prevent this caking problem.

- Keeping the additive stockpile under extremely dry and cool additive storage sheds not only retards the chemical oxidation reaction but also maintain their resistive nature against oxidizing components for the long duration.

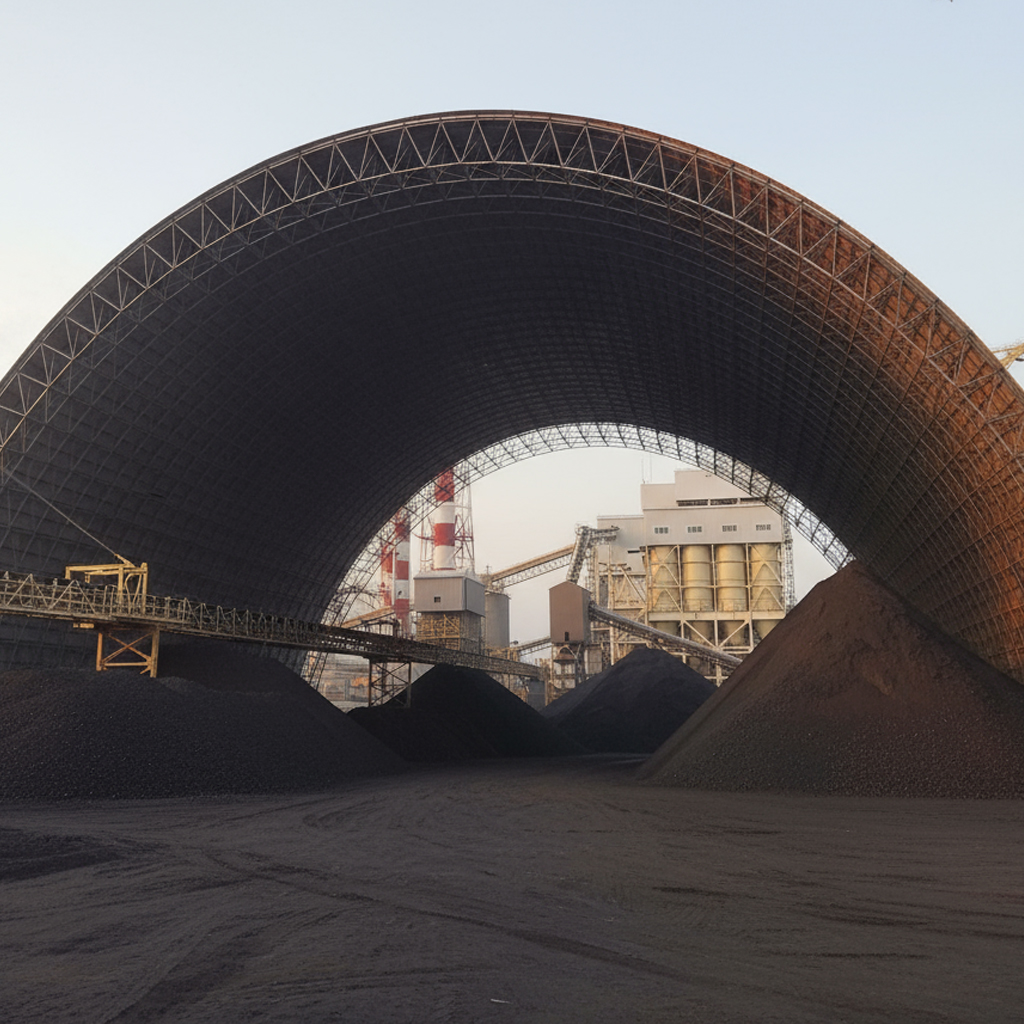

Additive storage shed, engineered by Hindustan Alcox Limited is advisable to cover stockpile for the most challenging environment. In addition to barrel vault structure, Additive Dome is also an appropriate choice for storing additives and covers large span to facilitate the storage of various additives under same shed. Hindustan Alcox Limited customizes additive dome after practically emphasizing the durability, strength and technical feasibility of structure with optimum space utilization.