About Hindustan Alcox - Space Frame Experts

With over 50+ years of experience, Hindustan Alcox is an industry leader in the fields of Engineering Procurement Construction (EPC) and heavy structure manufacturing.

Industry Experts

Our team of designers and engineers possesses extensive experience in projects related to airports, defence, multi-storey buildings, power plants, and cement and steel plants.

World Class Manufacturing

Precision Engineering

Design

Quality

Marerial Test Certificates, Manufacturing Test Certificates, Inspection Reports, Third Party Inspection Reports, Inspection Reports of packing & forwarding.

We have our own in-house testing facilities & qualified engineers to conduct tests as per standards. The test for mechanical properties & chemical compositions is performed at a government-approved Laboratory.

Strict Quality Control

Quality is ensured from the initial stage through defined documentation, skilled and experienced quality engineers and technicians, and rigorous testing using precision measuring instruments and advanced facilities.

Quality Assurance Plan

Defined as procedures & norms of engineering. Procurement, manufacturing, testing - acceptance norms, packing & forwarding & commission, etc.

NDT Inspection

We have in-house facilities with a qualified person for DA, MPI & UT.

We take the services from outside approved laboratories for RT & mechanical properties testing.

Third Party Inspection

The jobs manufactured / Process carried out by Alcox have been inspected, witnessed & accepted by reputed. Third-party inspection agencies, like Bureau Beritas.

Resources

- Provide a work environment that makes the employee committed & motivated for maximizing productivity. Establish systems for maintaining transparency, fairness & equality in dealing with the employees.

- Empower employees to enhance commitment, responsibility & accountability.

- Encourage teamwork, creativity, innovativeness & high achievement orientation.

- Provide growth & opportunities for developing skills & knowledge. Ensure the functioning of effective communication channels with employees.

- Provide orientation programs for new recruits & training-development program for employees.

Production

- The availability of state-of-the-art equipment is critical in deadline management in the industry.

- A well-staffed plant division, run by senior mechanical engineers, works closely with consultants and Architects to plan out various alternative techniques and provide necessary plant systems.

- A preventive maintenance program for all plant and machinery is mandatory at every site.

- The mechanical division maintains a complete inventory of spares so that repair downtime can be minimised and production schedules maintained. For the same reason, substitute spares for imported machinery are often designed in-house and ordered locally.

Products & Services

Airports

The integrated terminal buildings are designed with number of structural innovations. The key feature of airport structure is their long span roof covering with massive column spacing. The mega columns and large cantilevers make the structure unique. By using modular space frame structure supported by cantilevered columns makes the roof aesthetically good with doubly curved.

Learn More

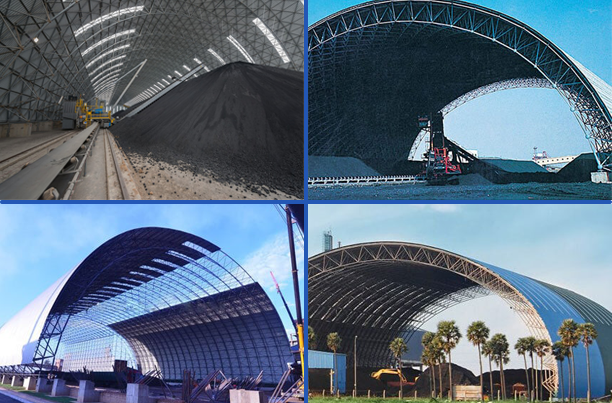

Bulk Storage Sheds

Bulk storage sheds are large span structure to accommodate tons of coals for continuous supply to the boilers.The structures are designed with modular space frame to make it cost effective compared to other conventional structures. Catwalks, ducts and other services can be accommodated within the top and bottom chords.

Coal

Space Frames

A space frame is a three-dimensional structure. The 3D behavior ensures optimum utilization of material. The quality of roofing is exceptionally good, as the deflections are almost negligible. Despite their light weight, these structures are designed to carry much heavier loads and have a huge spanning capacity. Erection time is minimal as the material is pre-fabricated from the factory.

Learn More

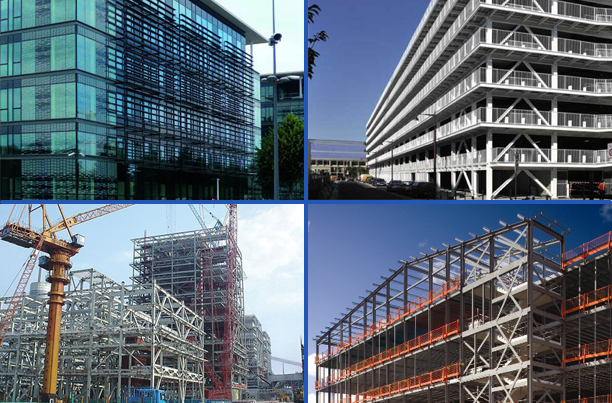

Multi-Storey Buildings

Steel frames construction is a very popular structural form for multi storey buildings as it provides great flexibility. The structure has adequate strength and stiffness to resist the applied loads due to gravity and wind. The function of the structure in resisting vertical loads due to gravity and horizontal loads due to wind is generally considered separately.

Learn More

Pre-Engineered Buildings

It offers a futuristic solution for creating durable and efficient structures in a cost-effective manner. Apart from great flexibility of designing and minimal construction time offered by PEB’s, they are also preferred for their robustness and durability. Moreover, it is possible to add a wide range of structural and non-structural components, which enhances their aesthetic appeal and also improves their usability.

Learn More

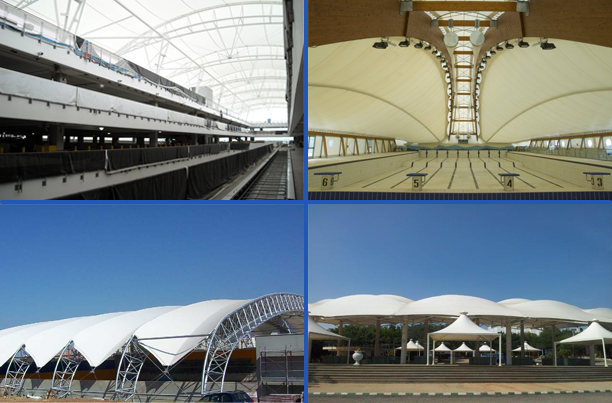

Membrane Structures

Textile supported by steel combines the high flexibility of use of this one, from reticular arches to infinite space geometries, with a singular covering applied only under optimum conditions in order to avoid abrasion and corrosion due to contact with the main bearing structure. The all-season use is guaranteed by a singular system of side opening in order to obtain maximum ventilation in the hot season.

Learn More

Self Supporting Roofs

A self-supporting roofing system makes it possible to erect a warehouse in one span without trusses, purlins, and rafters. The systems are mechanically sealed, which ensures better weather proofing and a hygienic and clean environment. The absence of holes, nuts, bolts, overlaps, or sealants, these structures require minimal to zero maintenance, making them highly cost-efficient.

Learn More

Suspended Facade Systems

In modern architecture and industrial construction, building facades have evolved much beyond simple external walls. Today, facade systems play a critical role in fire safety, thermal insulation, building performance, energy efficiency, durability, and architectural expression. Among the most advanced facade solutions used globally and in India, Suspended Facade Systems have gained significant importance.

Learn More