Large-span steel structures play a vital role in modern industrial infrastructure, especially in sectors such as mining, power generation, cement manufacturing, and energy processing. As industrial capacities expand and environmental regulations become stricter, industries increasingly rely on engineered steel storage sheds and enclosures to protect bulk materials, ensure operational efficiency, and reduce environmental impact.

Steel-based storage solutions provide flexibility in design, durability in harsh environments, and compatibility with large-scale material handling systems. These structures are commonly used to cover coal, iron ore, limestone, gypsum, additives, and other raw materials that require protection from weather and contamination.

Importance of Bulk Storage Sheds in Industrial Operations

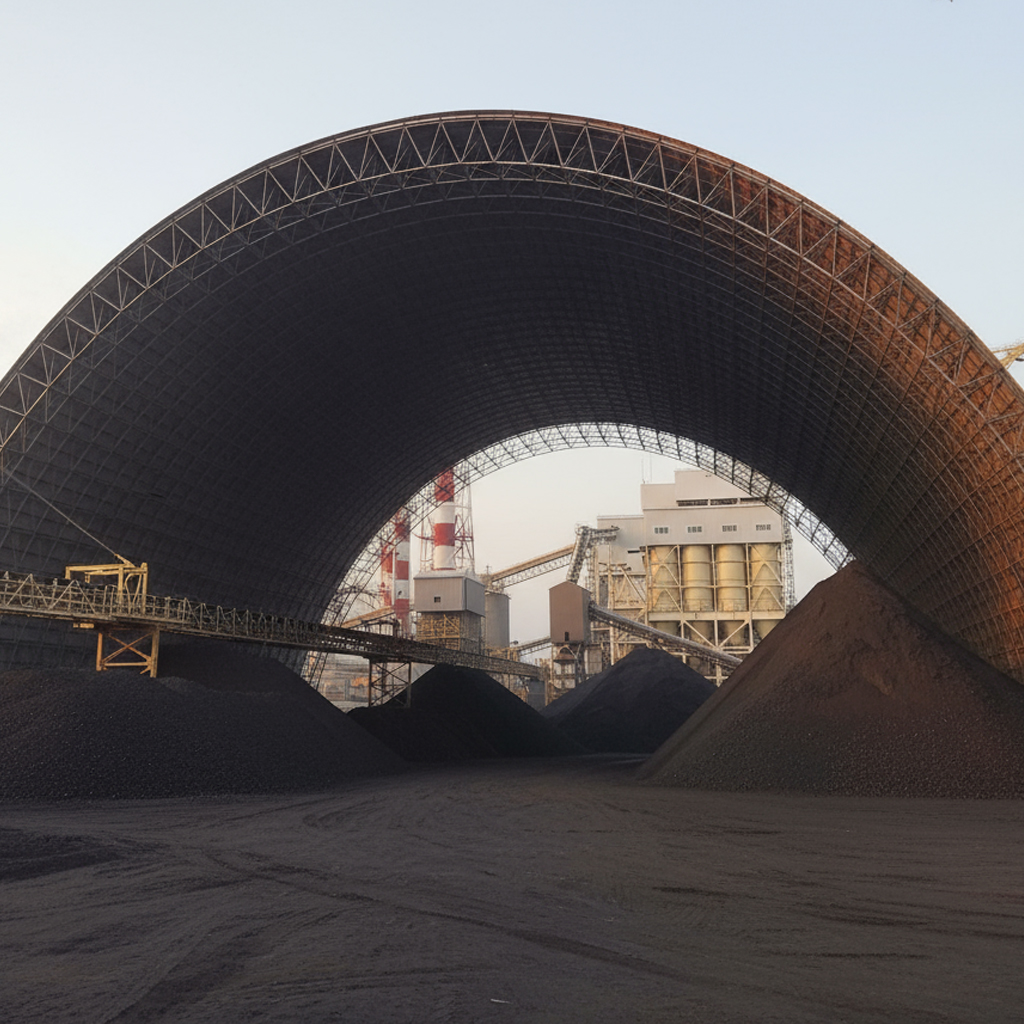

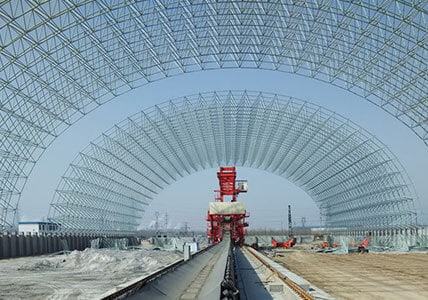

Bulk material storage is a critical component of continuous industrial operations. Coal-fired power plants, mining facilities, and cement plants depend on secure storage systems to maintain uninterrupted production. Bulk storage sheds are typically designed as large-span steel or space-frame structures, allowing vast quantities of materials to be stored under one roof.

Wide clear spans minimize internal obstructions, enabling smooth movement of stackers, reclaimers, and conveyors. Enclosed storage also helps control dust emissions, prevent material degradation caused by rain or wind, and improve workplace safety.

Common benefits of bulk storage sheds include:

- High storage capacity for coal, ores, and aggregates

- Efficient space utilization through long-span structural systems

- Environmental compliance by limiting dust and runoff

- Improved material quality through weather protection

Role of Steel Structures in Coal Gasification Facilities

Coal gasification is an advanced process that converts coal into synthesis gas (syngas), which can be used for power generation, fuels, and chemicals. Steel structures play a supporting role in coal gasification facilities by providing covered areas for coal handling, preparation, and auxiliary operations.

Long-span roofs, domes, and barrel-vault structures are commonly used to protect coal stockpiles and processing zones. These enclosures help maintain consistent feedstock quality, reduce material losses, and enhance safety in high-temperature and dust-prone environments.

Properly designed steel sheds also contribute to smoother plant operations by allowing efficient integration of material handling equipment while withstanding heavy loads, wind forces, and seismic conditions.

Steel Storage Infrastructure in Cement Plants

Cement manufacturing relies heavily on the quality and consistency of raw materials. Steel storage sheds are widely used in cement plants to cover limestone, clay, gypsum, additives, and finished cement. Enclosed storage prevents moisture ingress, maintains material composition, and supports efficient blending processes.

In addition to raw materials, steel structures are used to create covered storage and handling zones near crushers, conveyors, and packing areas. These structures are engineered to handle large loads while providing long service life under continuous industrial use.

Advanced design tools such as 3D modeling and structural analysis help ensure that storage sheds meet local environmental and structural requirements, including wind, seismic, and operational loads.

Growing Need for Engineered Storage Solutions

As industrial projects scale up and environmental standards evolve, the demand for engineered steel storage solutions continues to grow. Bulk storage sheds, coal handling enclosures, and cement material storage structures are increasingly seen as essential components of modern industrial facilities.

By improving material protection, operational efficiency, and environmental performance, steel storage infrastructure plays a key role in supporting sustainable and reliable industrial operations across multiple sectors.

Additive Storage and Safety

In addition to primary bulk materials, many industrial facilities handle additives such as silica fume, fly ash, and limestone powder. These fine materials require carefully designed storage solutions to prevent moisture absorption, material segregation, and caking, all of which can negatively impact processing efficiency and product quality.

Specialized additive storage sheds and dome-type enclosures are commonly used to address these challenges. Structural options such as barrel-vault roofs and large-span domes without internal supports allow for efficient material storage while maintaining unobstructed internal space. Features like controlled ventilation, moisture-resistant cladding, and sealed enclosures help preserve additive quality over extended storage periods.

Key advantages of engineered additive storage systems include:

- Optimized Storage Capacity: High-clearance structures allow greater on-site inventory without expanding footprint

- Improved Inventory Management: Structured layouts support easier material handling and monitoring

- Enhanced Material Protection: Enclosed environments reduce exposure to rain and humidity

- Environmental Safety: Contained storage minimizes dust dispersion and surface runoff

Industry observations highlight that well-designed additive storage sheds significantly improve handling efficiency and safety when managing sensitive powdered materials.