TURNKEY SOLUTION FOR ADDITIVE & SULPHUR STORAGE

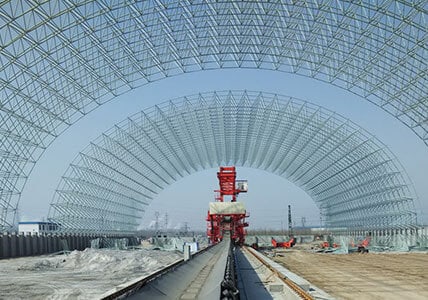

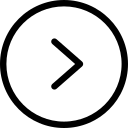

Hindustan Alcox specializes in storage solutions for additives with long span steel structure having span of up to 150m & height of up to 40m. Additive storage shed, engineered by Alcox is the best choice to cover stockpile for the most challenging environment. Additive storage (or slag storage) sheds are often built over operating stockpiles so that construction may proceed without interrupting operations. Because our erection process does not require machines to be installed in the periphery of the span. Some additives like sulphur/sulfur are highly corrosive in nature. Sulphur storage system is a very dynamic system, where many compounds & inappropriate conditions interact to form intervening compounds that can cause safety concerns. Corrosion free conditions under additive storage sheds & cross ventilation and prevention from adverse weather conditions make sulphur storage a viable solution.

Additive Storage

In addition to barrel vault structure, Additive Dome is also an appropriate choice for storing additives and covers a large span to facilitate the storage of various additives under the same shed. Hindustan Alcox customizes additive dome after practically emphasizing the durability, strength and technical feasibility of structure with optimum space utilization. We are leading additive storage, dome, stockpile and shed manufacturer, installation and all solutions including sulphur domes and sheds from last 50+ years in India and worldwide including Asia, Africa, UK & USA with assurance of quality.

Additive Dome

Additive Dome is a suitable option for storing additives in addition to barrel vault construction. It has a wide spread that makes it easier to store different additives under the same shed. We tailor additive domes, putting a practical emphasis on the structure’s strength, longevity, and technical viability while making the most use of available space.

Sulphur Storage

Sulfur requires special storage methods to avoid damage and harm to nature. At some point during the process, the sulfur will be held in either a solid or liquid state. Every year, significant amounts of sulfur are generated and stored to use as per the requirements.

Sulphur Dome

We offer sulfur domes with the turnkey solution to cover stockpiles in the most difficult environments. Its vast span allows for the storage of multiple additives beneath the same shed. We are well skilled in modifying the sulphur domes and stockpile shed. We are emphasizing on the structure’s strength, longevity, and technological viability while making the best use of available space.

Product Gallery

PRODUCTS & SERVICES

Airports

The integrated terminal buildings are designed with number of structural innovations. The key feature of airport structure is their long span roof covering with massive column spacing. The mega columns and large cantilevers make the structure unique. By using modular space frame structure supported by cantilevered columns makes the roof aesthetically good with doubly curved.

Learn More

Bulk Storage Sheds

Bulk storage sheds are large span structure to accommodate tons of coals for continuous supply to the boilers.The structures are designed with modular space frame to make it cost effective compared to other conventional structures. Catwalks, ducts and other services can be accommodated within the top and bottom chords.

Coal

Space Frames

A space frame is a three-dimensional structure. The 3D behavior ensures optimum utilization of material. The quality of roofing is exceptionally good, as the deflections are almost negligible. Despite their light weight, these structures are designed to carry much heavier loads and have a huge spanning capacity. Erection time is minimal as the material is pre-fabricated from the factory.

Learn More

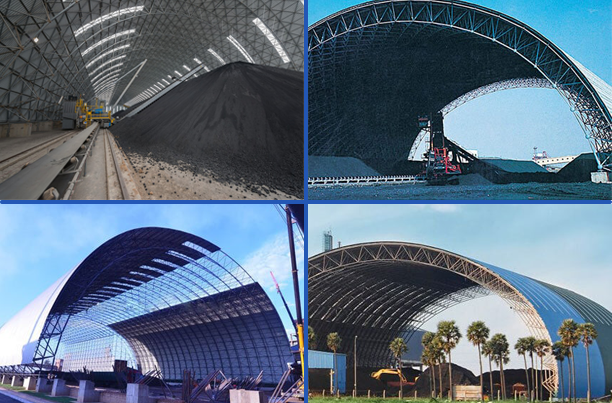

Multi-Storey Buildings

Steel frames construction is a very popular structural form for multi storey buildings as it provides great flexibility. The structure has adequate strength and stiffness to resist the applied loads due to gravity and wind. The function of the structure in resisting vertical loads due to gravity and horizontal loads due to wind is generally considered separately.

Learn More

Pre-Engineered Buildings

It offers a futuristic solution for creating durable and efficient structures in a cost-effective manner. Apart from great flexibility of designing and minimal construction time offered by PEB’s, they are also preferred for their robustness and durability. Moreover, it is possible to add a wide range of structural and non-structural components, which enhances their aesthetic appeal and also improves their usability.

Learn More

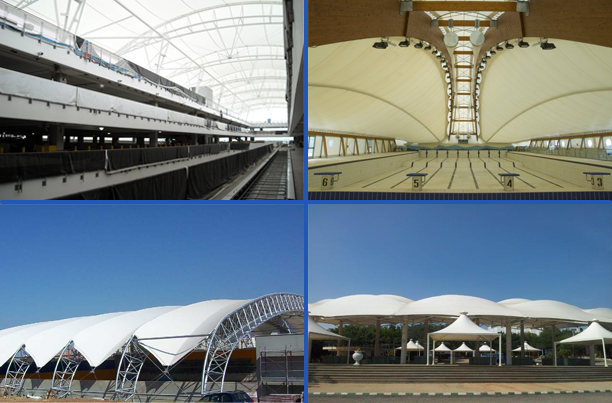

Membrane Structures

Textile supported by steel combines the high flexibility of use of this one, from reticular arches to infinite space geometries, with a singular covering applied only under optimum conditions in order to avoid abrasion and corrosion due to contact with the main bearing structure. The all-season use is guaranteed by a singular system of side opening in order to obtain maximum ventilation in the hot season.

Learn More

Self Supporting Roofs

A self-supporting roofing system makes it possible to erect a warehouse in one span without trusses, purlins, and rafters. The systems are mechanically sealed, which ensures better weather proofing and a hygienic and clean environment. The absence of holes, nuts, bolts, overlaps, or sealants, these structures require minimal to zero maintenance, making them highly cost-efficient.

Learn More