Turnkey Solution for Gypsum Storage

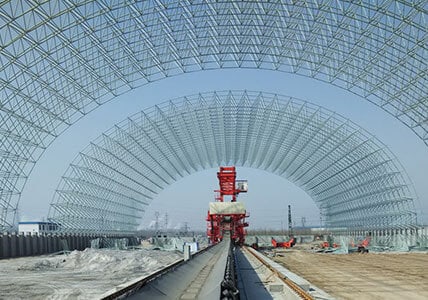

Hindustan Alcox specializes in storage solutions for gypsum with long span steel structure having a span of up to 150 m & height of up to 40 m. Gypsum storage shed, engineered by Alcox is the best choice to cover stockpile for the most challenging environment. In cement plants, Gypsum storage sheds are very effective for prevention and control of fugitive emission. Prevention from vulnerability caused by adverse environmental conditions is also one of the advantages of our gypsum storage sheds.

As an alternate to barrel vault structure, Gypsum dome is also an economical, fast and environmentally friendly storage solution. Hindustan Alcox customizes gypsum dome after practically emphasising the durability, strength and technical feasibility of the structure with optimum space utilization. We are a leading manufacturer of gypsum storage, domes, stockpiles, and sheds in India and overseas, including Asia, Africa, the UK & USA, with over 50 years of experience in ensuring quality and reliability.

FGD Domes & Sheds

Another application of Gypsum storage is FGD/Flue-Gas Desulphurization. In FGD, Chemical Techniques are used to exclude sulphur dioxide (So2) in exhausted flue gases from the Furnace/boiler. Some of the Chemical techniques used for FGD storage are ‘Wet Scrubbing’,’ Dry Scrubbing’,’SNOX FGD’ etc. We are manufacturing FGD dome and shed as per the international standards with the assurance of quality and durability.

Issues related to FGD Gypsum handling are usually dealt under a roofed storage shed, known as FGD sheds to avoid the accumulation of additional moisture from precipitation & to provide proper wind guards to prevent dusting.

OTHER APPLICATIONS OF OUR STRUCTURES

LIMESTONE STORAGE

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clay.

The limestone is excavated from open cast mines after drilling and blasting and then loaded onto dumpers, which transport the materials and unload it into hoppers of limestone crushers. The clays are excavated from open cast mines and loaded onto dumpers, which transport the materials and unload it into open yard storage.

As we know cement manufacturer or cement company operator have to ensure that their product maintain quality and consistent properties. But most of the limestone quarries produce material of varying chemical composition. To obtain consistent quality in final product, quarried raw material must be blended before it is fed into the kiln. With our structure, any amount of limestone can be stored

Although stockpiles are created by slewing stacker to minimize fugitive dust, most of the cement producers enclose their stockpile to protect the surrounding environment, and to prevent loss of material due to water runoff and wind.

Limestone storage sheds are the best choice to cover stockpile. It is a low cost solution because fabrication and erection of the structure takes less time. We provide solution for Bulk storage –

- In-house design, fabrication and erection of Limestone shed.

- Designing and pre-fabrication of component by using computers.

- Packaged and shipped in small units that can be by hand unloaded in remote locations.

- Assembled over a stock pile or stockyard while the stockyard remains in operation.

The construction systems uses mild steel in case of limestone shed, no welding is required because the connection of the member consists of a very efficient moment-resistant mechanical joint. Limestone shed may be built in single- or double-layer configurations, depending on the load and span for the application. Experience suggests that for the spans required in limestone covers, a-double-layer is the most cost-effective

Limestone storage shed are often built over operating stockpiles since construction can proceed without interrupting operations.

CLINKER STORAGE

Clinker consists of various calcium silicates including alite and belite. Tricalcium aluminate and calcium aluminoferrite are other common components. These components are often generated in situ by heating various clays and limestone.

Clinker consists essentially of four minerals:

- Alite: approximately tricalcium silicate (typically about 65% of the total)

- Belite: approximately dicalcium silicate (typically about 15% of the total)

- Tricalcium Aluminate: Typically about 7% of the total

- Tetracalcium Aluminoferrite: Typically about 8% of the total

Cement is caustic, so it can cause chemical burns. The powder can cause irritation or, with severe exposure, lung cancer and can contain some hazardous components such as crystalline silica and hexavalent chromium . Environmental concerns are the high energy consumption required to mine, manufacture, and transport the cement and the related air pollution, including the release of greenhouse gases (e.g., carbon dioxide), dioxin, NOx , SO2 , and particulates. Therefore, it is essential that clinker should be properly stored in covered sheds.

The construction systems uses mild steel in case of clinker storage, no welding is required because the connection of the member consists of a very efficient moment-resistant mechanical joint. Clinker storage shed may be built in single- or double-layer configurations, depending on the load and span. Experience suggests large spans are required in clinker storage , a-double-layer is the most cost-effective Clinker storage sheds are often built over operating stockpiles since construction can proceed without interrupting operations. Because our erection process does not require machines to be installed internal periphery of the span.

IRON ORE STORAGE

Our Iron Ore Storage Structure is fully Complying with new environmental regulations for air quality, Prevention and control of fugitive emission. Instead of investing in temporary solution, it is recommended to adopt permanent solution. Our solutions presented here not only allow affordable compliance, but also enhance the reputation of your plant. In addition, one time investment is much more economical than the periodic investments

LIGNITE STORAGE

Lignite-generated electricity is abundant, low-cost, reliable and environmentally compatible.”

Lignite is a dark brown to black combustible mineral formed over millions of years by the partial decomposition of plant material subject to increased pressure and temperature in an airless atmosphere. In simple terms, lignite, often referred to as brown coal, is a soft brown combustible sedimentary rock formed from naturally compressed peat. It is considered the lowest rank of coal due to its relatively low heat content. It has a carbon content around 25-35%.

Lignite is brownish-black in color and has a carbon content around 25-35%, a high inherent moisture content sometimes as high as 66%, and an ash content ranging from 6% to 19% compared with 6% to 12% for bituminous coal We would like to propose Large Span Steel Shed, which can be used to cover lignite; it can built with a span of up to 150 m and height of up to 40 m.The construction systems uses mild steel in case of lignite storage, no welding is required because the connection of the member consists of a very efficient moment-resistant mechanical joint. Lignite storage shed may be built in single- or double-layer configurations, depending on the load and span. Experience suggests large spans are required in lignite storage , a-double-layer is the most cost-effective. Lignite storage sheds are often built over operating stockpiles since construction can proceed without interrupting operations. Because our erection process does not require machines to be installed internal periphery of the span.

ADDITIVE STORAGE

Additives are chemicals and materials blended into base cement slurries to alter the performance of the cement. Due to the inherent nature of base cements (Neat, Portland and Pozzolanic) and because of the demands placed on the cement cover throughout the life of the structure, the performance properties of the cementing slurry are modified to address the specific and unique conditions of each structure.

Additives are used to enhance cement slurries in all wellbore conditions. Variations in additive concentration may cause significant changes in thickening time, compressive strength, and viscosity, so determining the optimum balance of additives to achieve a reliable annular seal, particularly in extreme or corrosive down hole conditions, can be complex. Thus, field-proven technical solutions, laboratory-driven empirical data from analytical tests, and finite element analysis models play an important role when engineering an optimized slurry blend Additive storage sheds are often built over operating stockpiles since construction can proceed without interrupting operations. Because our erection process does not require machines to be installed internal periphery of the span.

Product Gallery

PRODUCTS & SERVICES

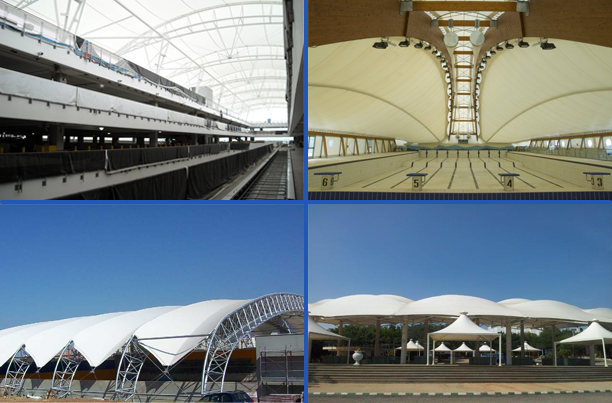

Airports

The integrated terminal buildings are designed with number of structural innovations. The key feature of airport structure is their long span roof covering with massive column spacing. The mega columns and large cantilevers make the structure unique. By using modular space frame structure supported by cantilevered columns makes the roof aesthetically good with doubly curved.

Learn More

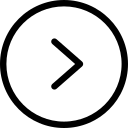

Bulk Storage Sheds

Bulk storage sheds are large span structure to accommodate tons of coals for continuous supply to the boilers.The structures are designed with modular space frame to make it cost effective compared to other conventional structures. Catwalks, ducts and other services can be accommodated within the top and bottom chords.

Coal

Space Frames

A space frame is a three-dimensional structure. The 3D behavior ensures optimum utilization of material. The quality of roofing is exceptionally good, as the deflections are almost negligible. Despite their light weight, these structures are designed to carry much heavier loads and have a huge spanning capacity. Erection time is minimal as the material is pre-fabricated from the factory.

Learn More

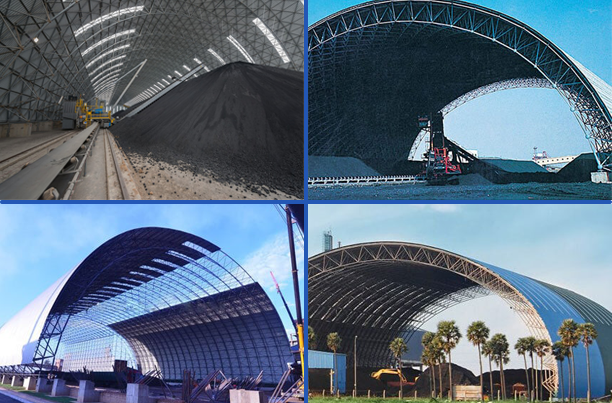

Multi-Storey Buildings

Steel frames construction is a very popular structural form for multi storey buildings as it provides great flexibility. The structure has adequate strength and stiffness to resist the applied loads due to gravity and wind. The function of the structure in resisting vertical loads due to gravity and horizontal loads due to wind is generally considered separately.

Learn More

Pre-Engineered Buildings

It offers a futuristic solution for creating durable and efficient structures in a cost-effective manner. Apart from great flexibility of designing and minimal construction time offered by PEB’s, they are also preferred for their robustness and durability. Moreover, it is possible to add a wide range of structural and non-structural components, which enhances their aesthetic appeal and also improves their usability.

Learn More

Membrane Structures

Textile supported by steel combines the high flexibility of use of this one, from reticular arches to infinite space geometries, with a singular covering applied only under optimum conditions in order to avoid abrasion and corrosion due to contact with the main bearing structure. The all-season use is guaranteed by a singular system of side opening in order to obtain maximum ventilation in the hot season.

Learn More

Self Supporting Roofs

A self-supporting roofing system makes it possible to erect a warehouse in one span without trusses, purlins, and rafters. The systems are mechanically sealed, which ensures better weather proofing and a hygienic and clean environment. The absence of holes, nuts, bolts, overlaps, or sealants, these structures require minimal to zero maintenance, making them highly cost-efficient.

Learn More