A space frame is one of the most advanced structural systems in modern construction. It combines strength, stability, and flexibility while covering vast areas without internal supports. Therefore, space frame structures are ideal for industries such as infrastructure, sports, aviation, energy, and industrial storage.

By using interconnected steel members arranged in geometric patterns, space frames distribute loads efficiently. As a result, they provide an excellent strength-to-weight ratio, making them a preferred choice for large-scale projects.

This article explores the concept of space frame structures, their benefits, applications, and why industries are increasingly turning to them for innovative and cost-effective solutions.

What is a Space Frame?

A space frame (or space structure) is a three-dimensional, lightweight, rigid structure. It is made of interlocking struts arranged in a geometric pattern, often based on triangles. Consequently, the load is evenly distributed, and the structure achieves high strength while using less material.

Key Features of a Space Frame

- Lightweight yet strong, thanks to efficient material distribution.

- Rigid and stable with minimal deflection.

- Modular design for easy assembly and disassembly.

- Cost-efficient in long-term construction and maintenance.

- Flexible applications in roofing, warehouses, stadiums, and more.

Advantages of Space Frame Structures

Strength and Durability

The triangular arrangement of members gives space frames incredible strength. Moreover, they can resist heavy loads and harsh environmental conditions, ensuring long service life.

Large Span Coverage

Unlike traditional beams, a space frame can cover vast distances without internal columns. Therefore, they are widely used in airports, exhibition halls, and sports stadiums where open space is required.

Cost-Effectiveness

Although the initial investment may be higher, space frame construction saves money in the long run. Reduced maintenance, faster installation, and durability result in long-term cost benefits.

Architectural Flexibility

Space frames can be shaped into domes, arches, pyramids, or flat roofs. As a result, architects enjoy greater creative freedom while maintaining structural integrity.

Lightweight Construction

Hollow steel sections make the structure lightweight. In addition, this reduces the overall dead load, making construction safer and faster.

Sustainability

Modern space frame structures often use recyclable materials. Consequently, they contribute to eco-friendly and sustainable construction practices.

Types of Space Frame Structures

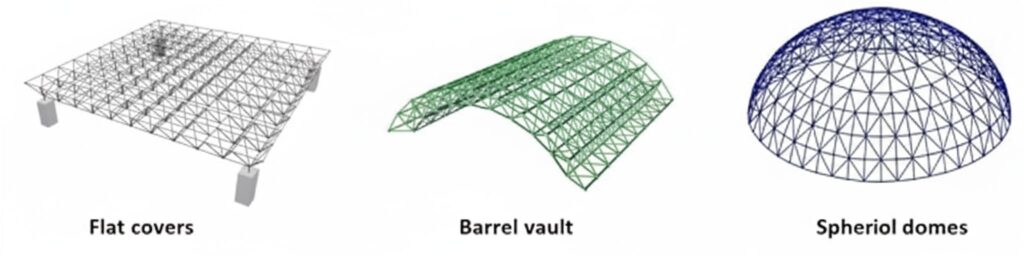

Single Layer Grid

- Consists of one layer of interconnected struts.

- Used for small-span structures like canopies.

- However, it offers less load capacity compared to other types.

Double Layer Grid

- Most common in large-span construction.

- Two layers of grids connected by vertical struts.

- Therefore, it provides excellent strength and rigidity.

Triple Layer Grid

- Designed for extremely heavy loads.

- Suitable for industrial storage domes and large-scale infrastructure.

- In addition, it allows maximum span coverage with superior stability.

Dome-Shaped Space Frames

- Spherical design, highly efficient in covering vast spaces.

- Popular in sports stadiums and exhibition halls.

- Moreover, the design distributes loads evenly across the surface.

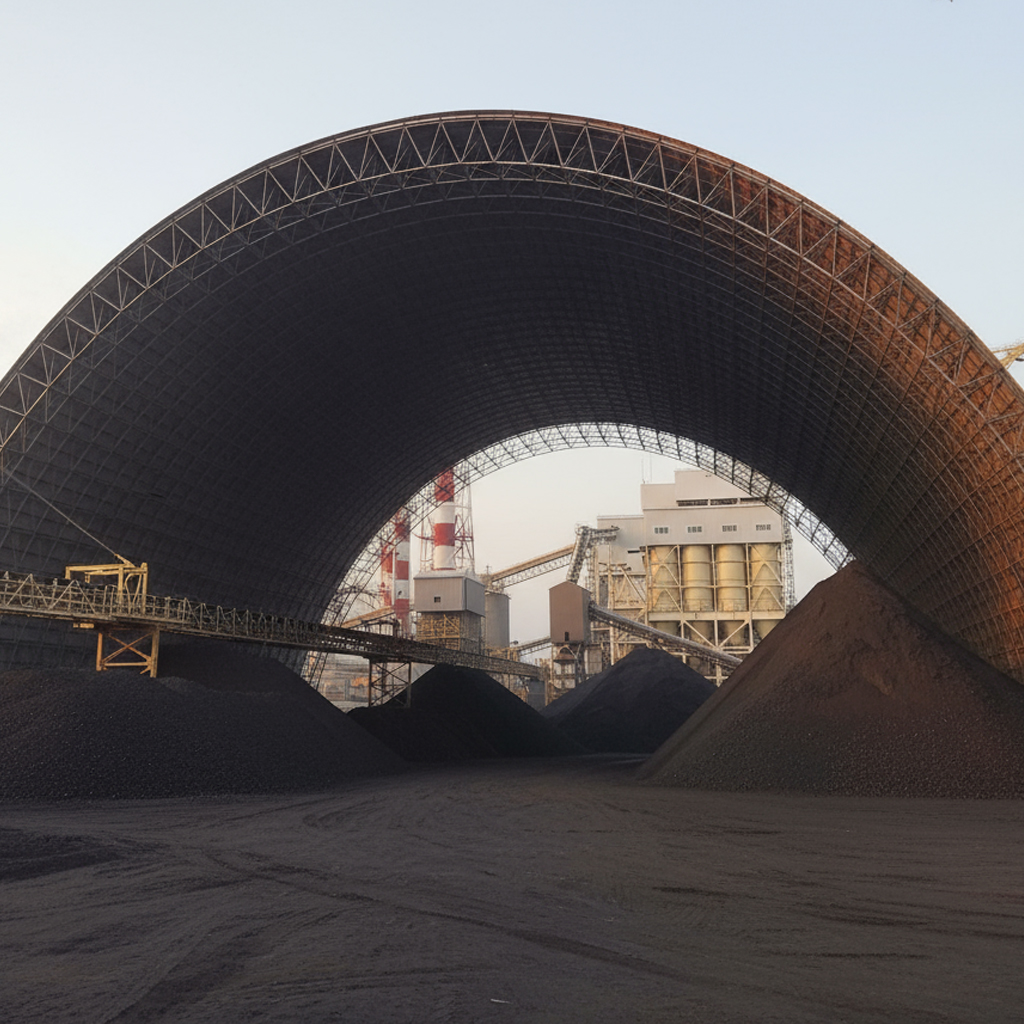

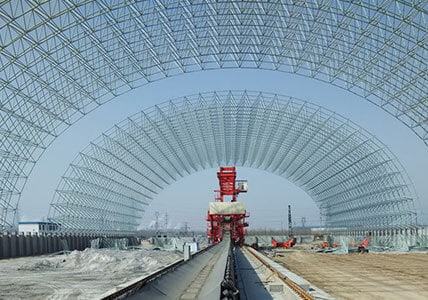

Barrel Vault Space Frames

- Arch-like structures covering long spans.

- Used in aircraft hangars and transportation hubs.

- Consequently, they provide both strength and visual appeal.

Applications of Space Frame Structures

Industrial Warehousing

Industries require large storage spaces for bulk materials like minerals, coal, and fertilizers. Space frame warehouses offer durability, low maintenance, and moisture protection.

Sports Stadiums and Arenas

Stadiums often use dome-shaped or barrel-vaulted space frames. Therefore, they allow large crowds to gather under safe, column-free roofing.

Airports and Transportation Hubs

Airports need wide-span roofing for terminals and hangars. In addition, space frames are lightweight, making them ideal for such mega projects.

Exhibition Halls and Convention Centers

These spaces demand flexibility and aesthetics. Moreover, space frames not only provide strength but also allow unique architectural designs.

Energy Sector

In power plants, refineries, and renewable energy facilities, space frame roofing systems protect equipment and ensure operational safety.

Commercial and Public Buildings

Shopping malls, auditoriums, and railway stations use space frame systems for their attractive design and efficiency.

Construction Process of a Space Frame

Design & Planning

Engineers analyze load requirements and design the frame geometry. Therefore, the choice of steel sections and connections is critical.

Fabrication

Steel members are fabricated with precision. In addition, advanced technology ensures dimensional accuracy.

Assembly

Modular components are assembled on-site. As a result, construction time is significantly reduced.

Installation

Using cranes and lifting equipment, the frame is installed in place. Moreover, minimal manpower is required compared to traditional construction.

Quality Checks

Structural stability and safety are thoroughly tested. Consequently, industries receive reliable and long-lasting structures.

Challenges in Space Frame Construction

- Initial Cost – Slightly higher than traditional methods.

- Skilled Labor Requirement – Requires trained engineers and technicians.

- Complex Design – Advanced software and analysis are necessary.

- Logistics – Transporting large prefabricated components may pose challenges.

However, these challenges are outweighed by long-term benefits, durability, and efficiency.

Future of Space Frame Structures

The future of space frame systems looks promising. With the rise of smart cities and mega infrastructure projects, demand for lightweight, sustainable, and durable roofing solutions will only grow.

- Integration of Smart Technology – Sensors to monitor load and stability.

- Use of Advanced Materials – Carbon fiber and composites for lighter structures.

- Eco-Friendly Construction – Increased use of recyclable steel and solar integration.

- 3D Printing in Construction – Faster and more precise fabrication.

Therefore, space frames will remain a vital part of global infrastructure development.

A space frame is more than just a structural system; it is a symbol of innovation in modern construction. Moreover, it reduces long-term costs, improves sustainability, and delivers unmatched strength.

As industries continue to evolve, space frames will play an even greater role in shaping the future of construction.

About Us – Hindustan Alcox Ltd

Hindustan Alcox Ltd specializes in designing and constructing advanced space frame structures, domes, and steel buildings for diverse industries. With decades of experience and a commitment to engineering excellence, Alcox delivers reliable, durable, and eco-friendly construction solutions that meet global standards.